This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Lean Principles: How do Manufacturers Recognize Culture?

How do manufacturers recognize culture?

Culture is invisible; it’s the “way we do things.” However, recognizing work culture in a manufacturing environment is essential for Lean production processes. For instance, culture allows employees to work on autopilot during the day, because it is a collection of habits and practices carried throughout a manufacturing company.

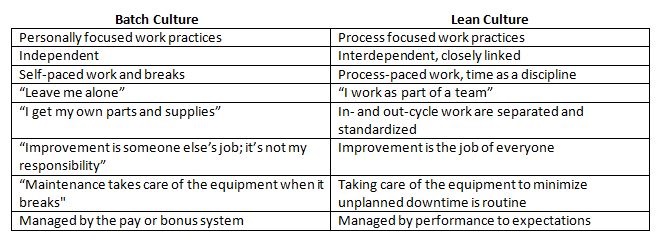

According to Creating a Lean Culture: Tools to Sustain Lean Conversions by David Mann, culture differences between a batch and Lean culture include:

Manufacturers that wish to “break” batch culture habits need to practice habits that make the workday more efficient. For instance, to achieve a Lean culture, manufacturers need to stop:

- Keeping a quantity of extra material, for “just in case.”

- Reordering more than needed when handling shortages, just to be sure you get enough.

- Always keeping the production line full in case something goes wrong.

- Starting a task early when information is not available from the upstream department.

- Leaving improvement process to the “experts.” Improvement strategies should begin with employees working on the shop floor.

- Continue working around a problem instead of solving it immediately, consequently, pushing off the problem.

Likewise, manufacturer’s implementing Lean culture habits need to make sure they don’t slip back into old habits. If a manufacturer stops following through Lean habits, they will soon face unstable and out-of-control processes that will require reinstituting Lean habits all over again. Therefore, get your entire team on board, work together, and create a better culture as one.

Interested in Lean manufacturing principles?

Read our blog post, 4 Top Misconceptions on Lean Manufacturing.

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.