This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Microsoft Dynamics 365 in Distribution: Order Promising – Available to Promise (ATP)

Microsoft Dynamics 365 Finance and Supply Chain Management is Microsoft’s premium business application suite, which was purposely built for modern distributors. Combining world-class Azure technology and infrastructure with best practice business processes and fully integrated analytical reporting, Dynamics 365 can relieve the pains that are very common within the distribution space, such as promising delivery dates.

With robust capabilities to plan, manage, and distribute inventory across multiple companies, currencies, and languages, D365 surfaces the information for you to understand the key trends and analysis and what is driving your enterprise. From intercompany planning to warehouse management with mobile barcode scanning capabilities, Dynamics 365 is built with the functionality to empower employees, enhance user experience, and create efficiencies within your business.

For this article, we’re going to focus on how Dynamics 365 Supply Chain Management allows you to reliably promise delivery dates to your customers and successfully deliver on those promises. D365 has functionality called Order Promising that will calculate the earliest ship and receipt date, and is based on the delivery date control method, including number of transport dates. You can select among four different delivery date control methods between sales lead times, ATP or available to promise, ATP + Issue margin, or CTP, capable to promise for some of our manufacturing folks.

How to Set Up Order Promising in D365

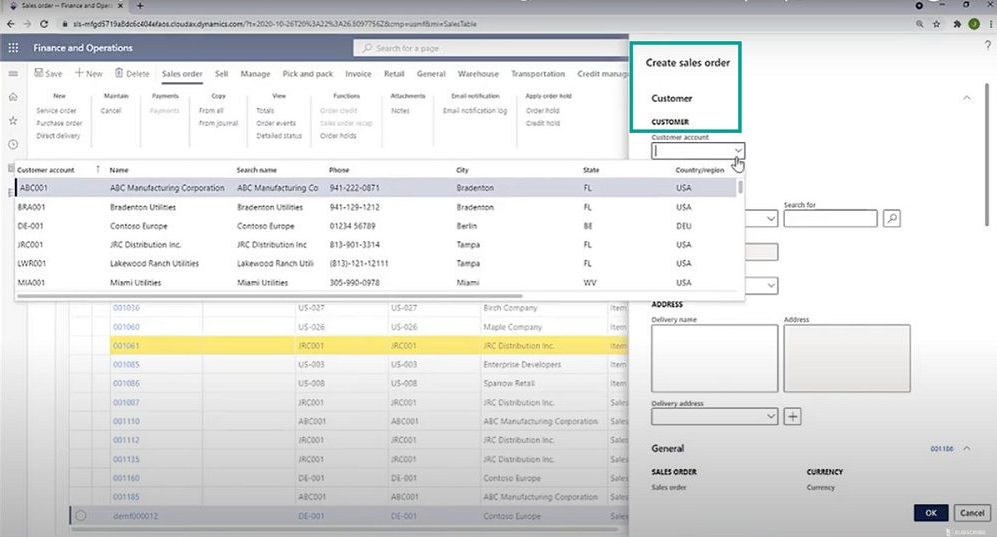

Within the Dynamics 365 application, start by navigating to create a new sales order from the Sales Order Processing Workspace. Select My Customer. A lot of the information can be set as a default on this source customer record, things like payment terms, delivery terms, delivery site, and warehouse.

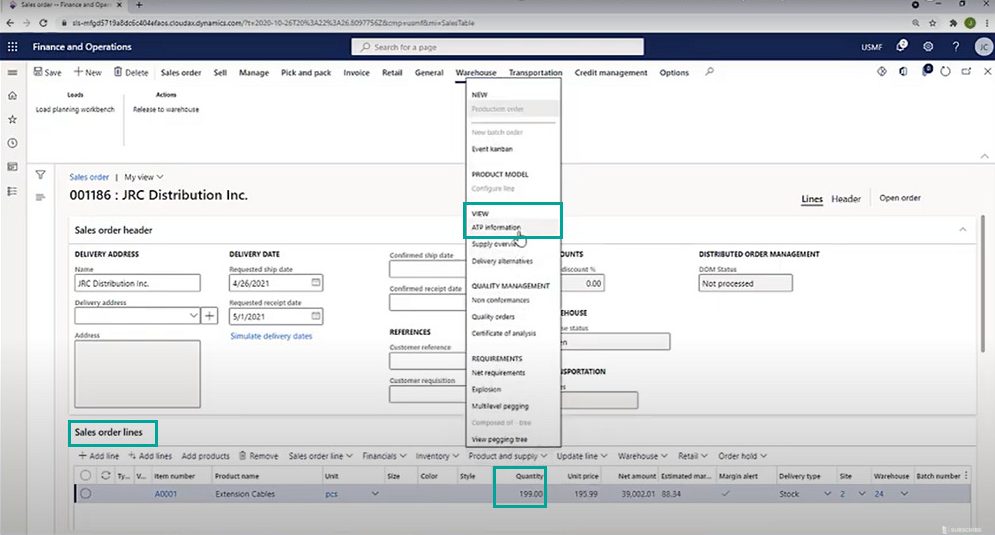

From there select My Delivery Date Control options, which consists of ATP, CTP, sales lead time and ATP + Issue margin. Within the Sales Order lines, I can begin the process by selecting My Item number or searching for item name.

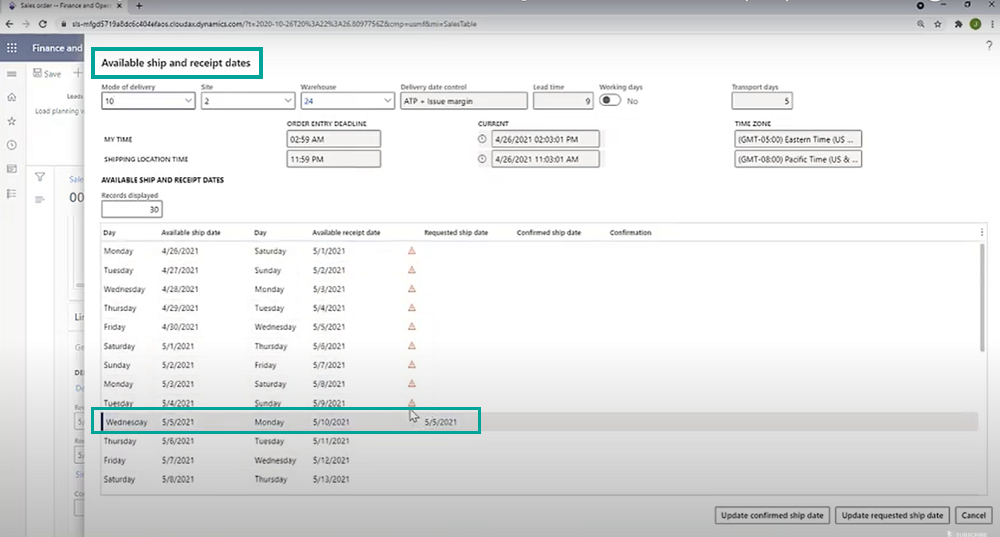

Once I’ve selected the record, entered the quantity, and saved the line, Dynamics 365 will calculate the earliest ship date based on that delivery date control method that we picked earlier. Directly from the sales order line, I can also view the ATP information either in graphical or numerical form. This will include uncommitted inventory, lead times, plan receipts, and inventory issues.

In addition to all of the ATP data, Dynamics has the capability to simulate delivery dates based on delivery methods, quantities, and lead times. The visibility and understanding of these inventory levels, including both outputs and inputs will drive your business to operate more efficiently, deliver your goods on time, and create goodwill with your customers.

You can see this full process in our 3 minute demo video show at top of this article.

Have any questions about setting up order promising and ATP in D365? Please contact us at any time!

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.