This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

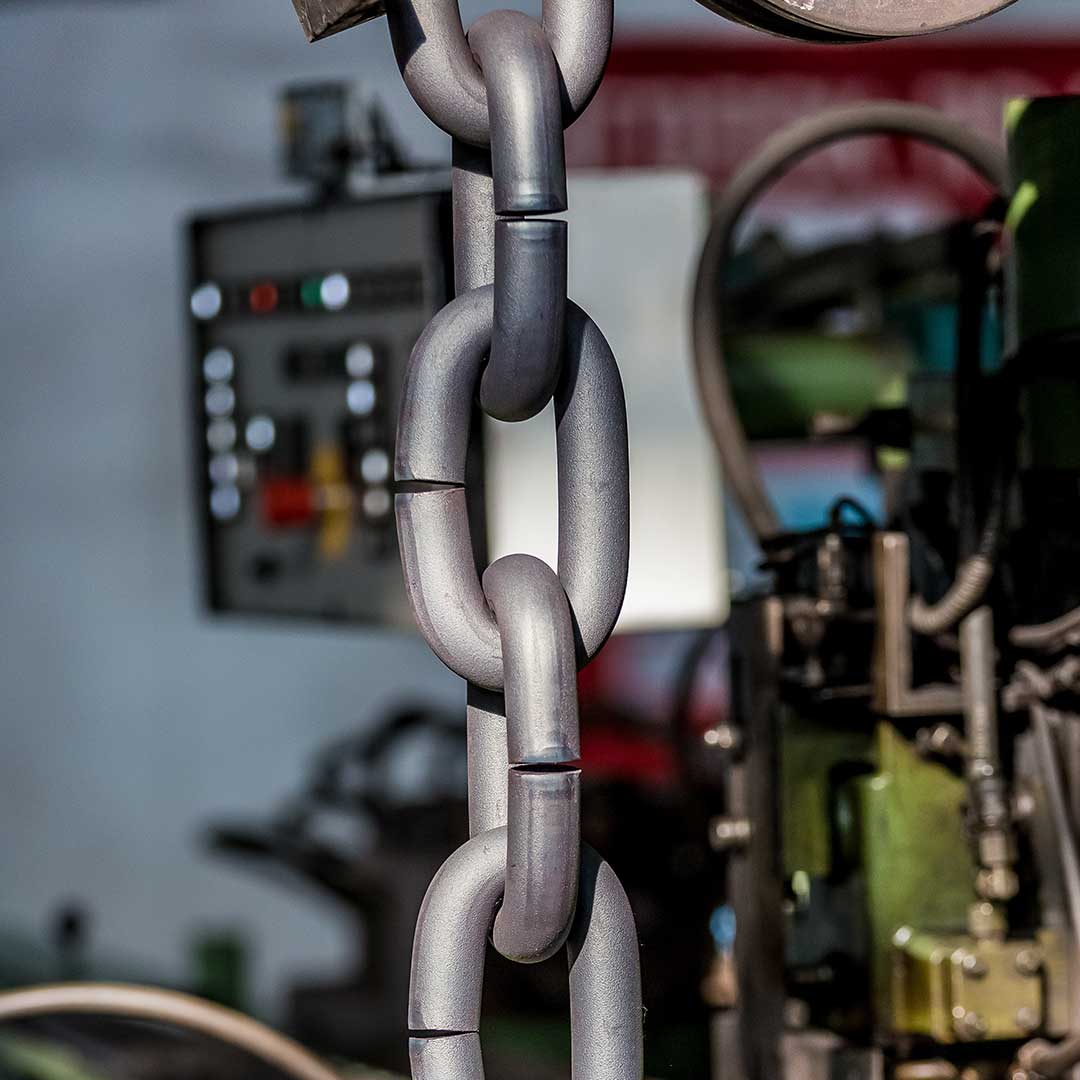

Revolutionize Manufacturing with Blockchain

Blockchain is yet another—excuse the pun—link in the Internet of Things chain that can set manufacturers to outpace their competition. Whereas the Internet of Things connects equipment to the business network and thus to mobile devices, blockchain can take this connectivity one step further. In particular, blockchain can revolutionize how manufacturers manage their supply chains.

Blockchain is a digital ledger technology that can store and record transactions. It’s most commonly recognized as Bitcoin and other cryptocurrencies. However, blockchain doesn’t have to be a cryptocurrency, like Bitcoin. Many industries are already finding applications for it, and manufacturers are only just coming around to the idea for coordinating their supply chains.

Blockchain Brings Transparency and Accountability

A manufacturer’s supply chain is often vastly complex, which can make complete transparency challenging. It’s especially challenging when the manufacturer builds and ships new equipment as well as service parts. By entering in each transaction of the supply chain into the blockchain, everyone across the company can see the status of each and every part coming in to the factory. This way, the finance department knows when it’s time to bill for services. Various production departments know when they can proceed with their portion of the order. Most importantly, customer service can easily tell customers the status of their orders.

In addition, the transparency makes it even easier to track down faulty parts. If a company learns after the fact that a part installed in their equipment is faulty, they can look at the blockchain to learn two things almost instantly:

- which supplier is responsible for the faulty parts; and

- which customers have the faulty parts.

From there, the company can immediately notify their customers of the problem and bring them in for replacements before they even have a problem. The company can also contact the problem supplier without a delay due to time tracing the source of the parts back to suppliers. As a whole, this process is far more efficient and far less costly thanks to the blockchain tech.

Blockchain Downsides for Manufacturers

This tech is still fairly new, and the application possibilities for manufacturers have not fully been explored. It’s early, meaning first-movers will see varying results without crystal clear strategy and long-term vision.

Also, manufacturing firms still using “legacy” ERP systems instead of the cloud will have to completely reorganize their company infrastructure. Since these older systems were created before all this came to pass, that could be a costly endeavor.

That said, however, it will be the manufacturers who embrace new technologies that will outpace their competition by a mile. It may be in its infancy stage and still evolving, but manufacturers that join in before it evolves will be the ones standing out from the status quo when new features and applications evolve.

There’s no time like the present to look into leaving the legacy systems for a complete digital transformation.

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.