In Microsoft Dynamics 365 for Finance and Operations (D365FO), there are a quite a few ways for warehouse workers to pick items for different types of orders. The most basic way is to generate a picking list for each sales order. However, our focus is on the recent release of consolidated picking for sales orders lines, called “Pick Line Grouping” using Advanced WMS on mobile devices.

Pick Line Grouping

Consolidated picking existed in versions prior to D365FO, and it was typically used in a warehouse management environment. It allowed warehouse workers to generate one picking list for multiple orders. The key to consolidated picking is that if you have multiple sales orders for the same item on a picking route, it’s ideal for the picker to have the ability to pick all of those items at the first stop on the route.

For example, if there were five sales orders on a route for five of the same item, the mobile device should prompt the picker to pick five items when arriving at the routed location. They would have the ability to enter and confirm a quantity of five, rather than scanning the same item five times. For more details go to https://docs.microsoft.com/en-us/dynamicsax-2012/appuser-itpro/picking-methods

However, consolidated picking for warehouse management was not available in D365FO until the release with “Pick Line Grouping.” Pick line grouping is used within the existing D365FO wave picking process. The work orders’ pick lines within the wave are consolidated based upon matching dimension set (i.e. Item ID and Location ID). The multiple matching pick lines are combined into a single pick execution step on the mobile device with the summed quantities to pick. This way, the warehouse worker will only have to go to the pick location one time for a single work order containing the matching pick lines.

As mentioned in the WMS Newsletter March 2019-2:

This feature offers faster execution of picking work and reduce worker pick path significantly in certain scenarios. The functionality is applied automatically via the setup to the mobile device. All matching pick lines and associated transactions of the work order being processed will be updated by the system mutually. The work order structure will remain as initially created and the lines will not be aggregated within the client. However, the pick lines should be sorted by Item Id for this functionality to work.

To use “Pick Line Grouping” at this time, the SQL statement below must be run to enable the flight. Once the SQL statement is run, the IIS will need to be restarted. To check if “Pick Line Grouping” is available, go to “Mobile device menu item” page and confirm that “Group pick” field is displayed.

INSERT INTO SYSFLIGHTING (FLIGHTNAME, ENABLED, FLIGHTSERVICEID)

VALUES (‘ WHSPickLineGroupingFeaturePreview ‘, 1, 12719367)

If for some reason if “Pick Line Grouping” is still not available, try with a “0” value in the SQL statement.

INSERT INTO SYSFLIGHTING (FLIGHTNAME, ENABLED, FLIGHTSERVICEID)

VALUES (‘ WHSPickLineGroupingFeaturePreview ‘, 1, 0)

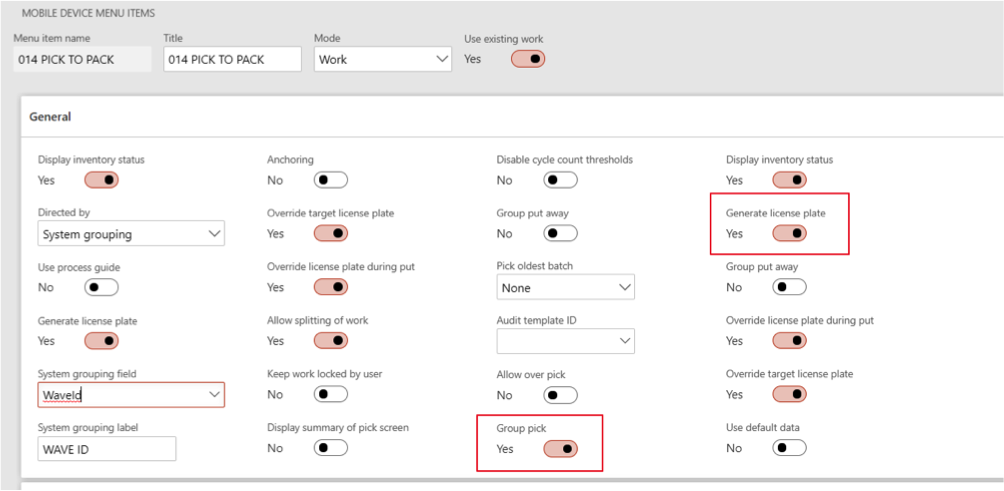

Once the flight is successfully enabled, create a Mobile device menu item and set “Group pick” to “Yes.” Also, for our example below, “Generate license plate” is also set to “Yes.” Familiar to experts already, the transaction requires a License plate to be entered or generated.

Example

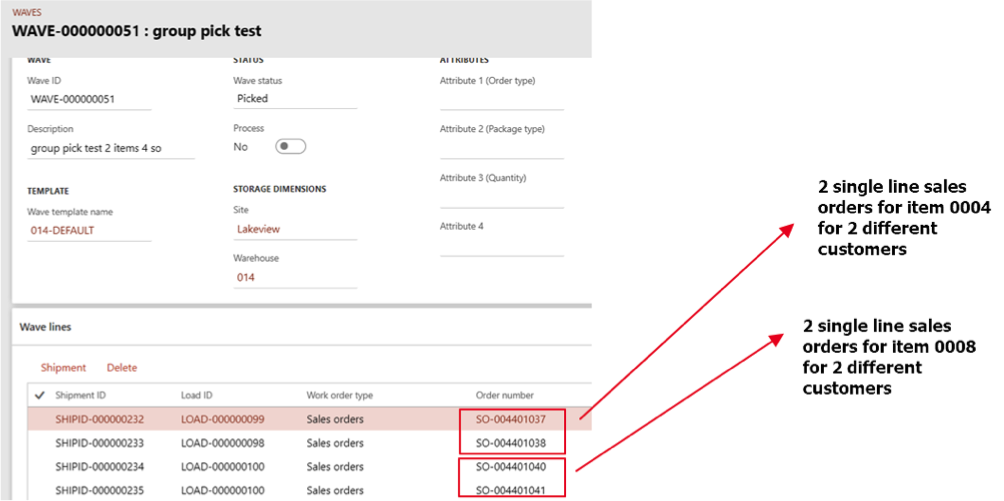

In the following example, a picking wave is created for four sales orders and each sales order is for a different customer. Each sales order has a single line item with quantity of one each. Two of the sales orders contains the same sales line item 0004 while the other two sales order each contains a sales line for the same item 0008.

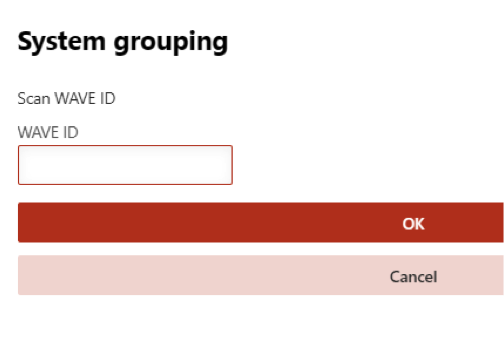

Using the mobile device, scan the wave to begin the picking process.

Using the mobile device, scan the wave to begin the picking process.

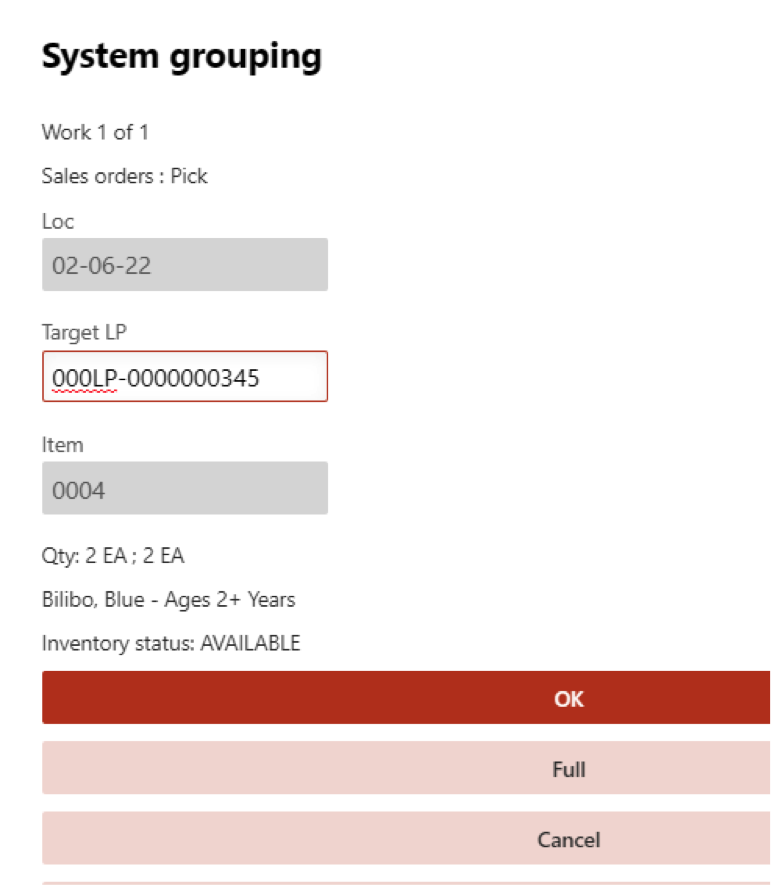

First stop on the route shows the system group pick for the first two sales orders. As you can see below, the system shows that a quantity of two each should be picked for item 0004.

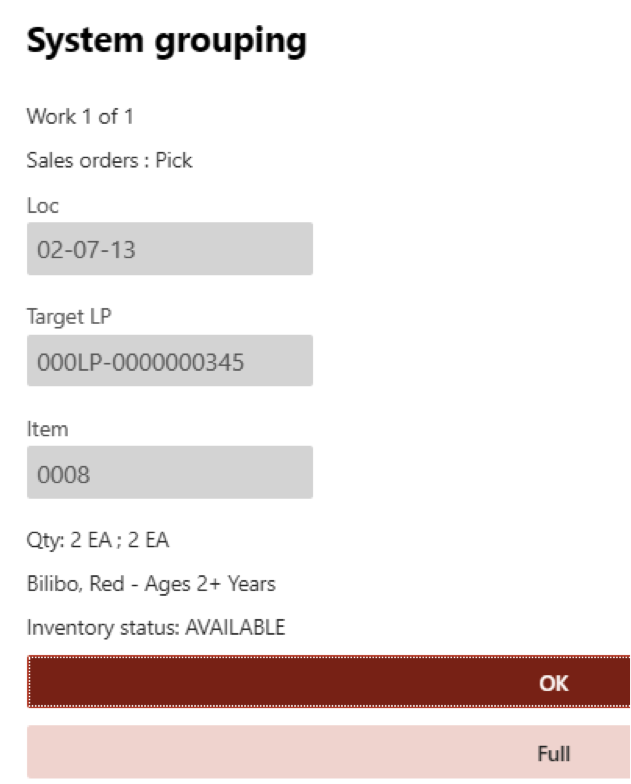

Next stop on the route shows the next two sales orders being grouped pick. As you can see below, the system shows that a quantity of two each should be picked for item 0008.

Work Confirmation Setup Issue

Work Confirmation Setup Issue

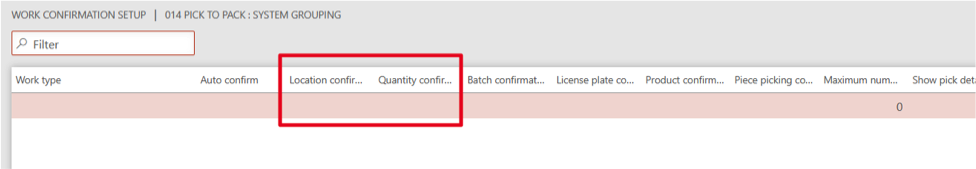

One thing to note about this newly released feature is that it currently does not work with work confirmation. Pick line grouping works great without confirming the location or quantity.

An incident number 119051322002391 has been created and reported to Microsoft for this work confirmation setup issue. Microsoft has identified that this issue is a product bug and a solution will be delivered into a future release. The link below contains details for the issue and the Notify me option can be used to receive updates on the resolution of the bug.

Wave Picking with Group Pick vs. Cluster Picking

Below list a few areas where Cluster picking and Wave picking differs.

Cluster picking

- Typically picking to a bin or a cart, usually containing smaller totes

- Useful for production batches

- Different license plate for each work ID

- Picking is put into separate bins for each work ID

- Allows for workers to pick multiple items from a single location for multiple work orders at the same time.

Consolidated (Grouped) Wave picking

- Typical for operations with a large number of sales orders or SKUs to be picked

- Multiple orders can be combined into one picking list

- One picking list for multiple orders for different customers and items

- Same license plate for each work ID

- Picking is put into one bin for all the orders

- (Wave picking with Group pick) Allows for workers to pick item for multiple matching pick lines from a single location for single work order.

For more details on Cluster picking, go to https://docs.microsoft.com/en-us/dynamics365/unified-operations/supply-chain/warehousing/set-up-cluster-picking.

For more details on Wave picking, go to https://docs.microsoft.com/en-us/dynamics365/unified-operations/supply-chain/warehousing/tasks/configure-wave-processing.

Have any other questions about Dynamics 365 Consolidated Picking? Feel free to contact us at any time!

Written and researched by Scott Adams, MCP and Ha Peng, respectively

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.