This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- Audit and Assurance

- Business Succession Plan

- Business Transformation

- Cloud Services

- Consulting Services

- CRM and ERP Products

- CRM Services

- Cybersecurity

- Data and AI

- ERP Services

- Forensic and Valuation

- Governance, Risk and Compliance

- HEADSTART Implementations

- Human Capital Management and Payroll

- Insurance Services

- Internal Audit

- Contact

- Services

- Audit & Assurance

- Business Succession Plan

- Business Transformation

- Cloud Services

- Consulting Services

- CRM and ERP Products

- CRM Services

- Cybersecurity

- Data and AI

- ERP Services

- Forensic & Valuation

- Governance, Risk and Compliance

- HEADSTART Implementations

- Human Capital Management & Payroll

- Insurance Services

- Internal Audit

- Investment Banking

- Lender Services

- IT and Managed Services

- Marketing and Communications

- Modern Workplace

- Outsourced Accounting

- Regulatory, Quality & Compliance

- Site Selection & Incentives

- Spend Management

- Tax

- Transaction Advisory

- Wealth Management

- Workforce Risk Management

- Industries

- Construction & Real Estate

- Discrete Manufacturing

- Federal Government

- Financial Services

- Government Contractors

- Industrial Equipment Manufacturing

- Life Sciences

- Manufacturing and Distribution

- Not-for-profit

- Process Manufacturing

- Professional Services

- Rolled Products

- State & Local Government

- Title IV Audit & Consulting

- Distribution & Supply Chain

- Insurance

- Insights

- About

- Locations

- Careers

- Pay

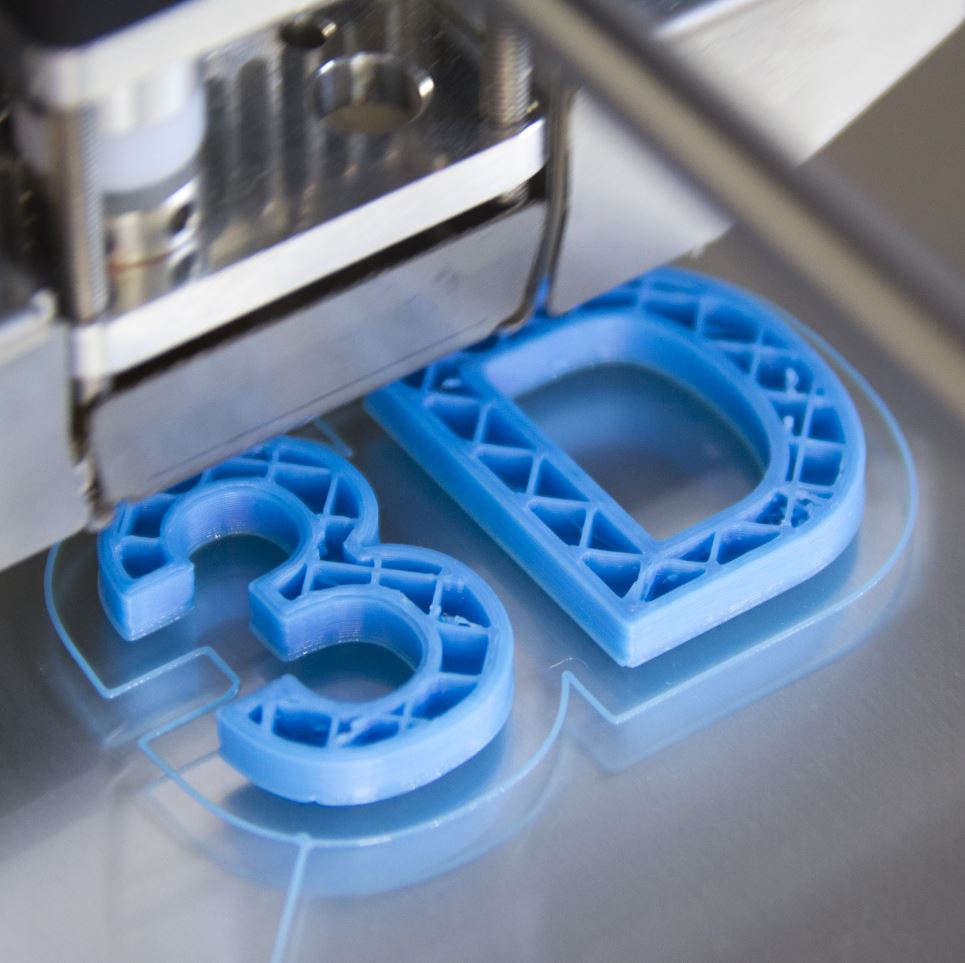

Could Your Next Flight be 3D Printed? – Large Scale 3D Printing

Large scale 3D printing in the manufacturing and distribution industry, also known as additive manufacturing, operates as an alternative to manually building parts. From medical device production to aerospace engineering, large scale 3D printing offers the potential to achieve a better approach to building three-dimensional solid objects.

Large Scale 3D Printing and its Benefits

3D printing creates parts and structures from digital designs by adding layers of material together to create complex shapes, using plastic, metal, glass, and more. Compared to alternative manual procedures, large scale 3D printing decreases production time and manual labor. In some cases, additive manufacturing skips steps that are taken with non-3D printing techniques. Additive manufacturing, additionally, creates objects that are lightweight and entirely customizable in shape.

While large scale 3D printing is expensive, the process of designing and erecting large structures or parts is often simplified when printed using additive manufacturing. Thus resources and time are decreased and typically result in expenses being close in range to alternative non-3D printing options. From ideation to completion, the time it takes to fulfill a large scale 3D printing project is shortened because objects are created directly from digital design.

The Future of Flight

Currently, aircraft designers and manufacturers use additive manufacturing to print cosmetic interior aircraft parts. This includes vents, door latch components, arm rest caps, and more—simplifying the production of interior cosmetic parts and applications. While not entirely glitzy, large scale 3D printing is likely only going to grow from here. Will your next flight be 3D printed? The short answer is no. However, your next flight may likely feature 3D printed objects throughout your cabin, and you won’t even know the difference from previous flights before.

According to Global Industry Analysts, Inc., the 3D printing market is expected to reach nearly $10 billion by 2020. The aircraft manufacturing industry, being one of the first to consistently utilize additive manufacturing for parts and structures, continues to support large scale 3D printing. As additive manufacturing advances, so will industry involvement.

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.

About the Author

Sikich

Sikich is a global company specializing in technology-enabled professional services. With more than 1,900 employees, Sikich draws on a diverse portfolio of technology solutions to deliver transformative digital strategies and is comprised of one of the largest CPA firms in the United States. From corporations and not-for-profits to state and local governments and federal agencies, Sikich clients utilize a broad spectrum of services* and products to help them improve performance and achieve long-term, strategic goals. *Securities offered through Sikich Corporate Finance LLC, member FINRA/SIPC. Investment advisory services offered through Sikich Financial, an SEC Registered Investment Advisor.

Sign up for Insights

Join 14,000+ Business executives and decision makers.

Latest Insights

Technology

From Paper to Automation: Rethinking Shop Floor Reporting

December 18, 2024

Manufacturing>Equipment manufacturing

The Impact of AI in Equipment Manufacturing

December 11, 2024

Sikich On Demand

On Demand – Manufacturers vs. Hackers: Tackling Cybers...

November 7, 2024

Technology

How Manufacturers Can Overcome 7 Common Production Pains wit...

October 30, 2024

News Release

Sikich Manufacturing Industry Pulse Survey Shows Executives&...

October 30, 2024

Dynamics 365>Dynamics 365 Business Central

Top 10 Ways to Simplify Operations in D365 Business Central ...

October 21, 2024

Dynamics 365

5 Tips to Minimize ERP Implementation Disruption

October 9, 2024

Manufacturing

Manufacturers’ Path to the Cloud: Where Do They Stand?...

October 3, 2024

Tax

The Ins-and-Outs of Employment Tax Credits for Manufacturers...

September 26, 2024

Site Selection

3D Printing: Tax Incentives for Manufacturers

September 12, 2024