This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Sikich ERP (D365) Solution Success in ETO Manufacturing

Sikich is a veteran consulting services company in the Engineer-to-Order (ETO manufacturing) vertical. We have faced very similar business requirements every time and have habitually expanded Dynamics 365 for Finance and Operations (D365FO) with third-party applications that address the most pressing ETO requirements.

In addition, Sikich added some functional enhancements regarding revision control. We also developed a list of recommended prefiltered tiles in Purchasing and Production and planning Workspaces that help control the extensive information stream from customer to engineering and from engineering to operations that is typical for this vertical.

Extensive use of the Project module

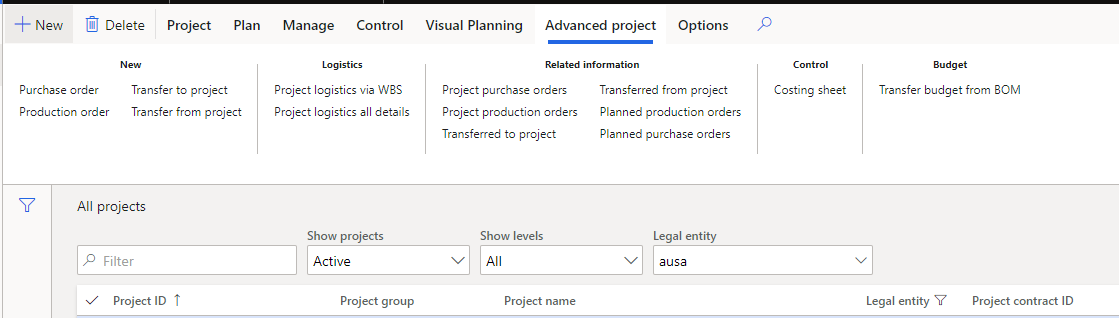

The use of the Project module is a must in the ETO vertical. Sikich is teaching customers the fine details of this module to get the maximum insight in revenue versus cost and conformance to the project schedule. Customers are using the project hierarchy extensively to track the cost of things like project scope change, warranty, goodwill, and others. Additionally, the feature of the Work Breakdown Structure is a necessity. Engineering and material planning must be coordinated with one plan, which is what the Project WBS provides.

With project templates and WBS templates, customers can build a new project quickly. Sikich will soon have an interface where CE Field service work orders report their cost to the Project module, allowing “Life Cycle Costing” for equipment sold to customers. This a “must-have” for many project accountants in this vertical.

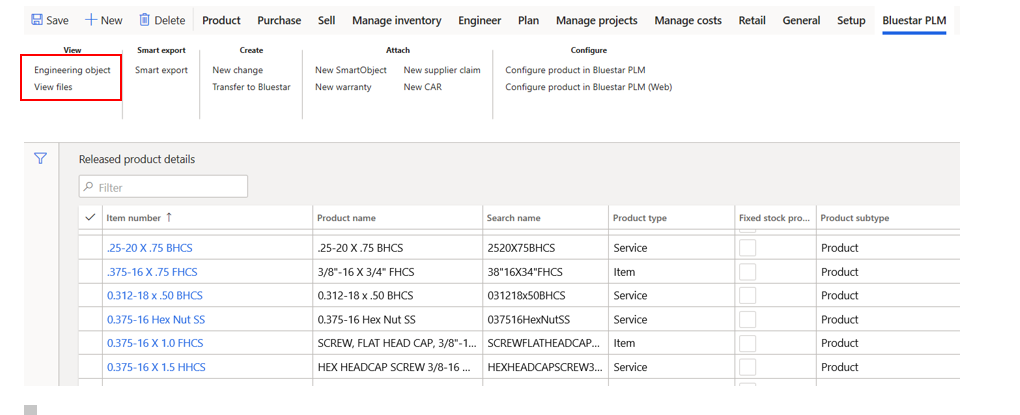

Engineering-Operations interaction: PLM and ERP closely integrated

This functional area is on the cutting edge of any software solution for this industry vertical. The significant involvement of engineering in every sale leads to the creation of many new part numbers and many new Bills of Material that need to find their way to Operations quickly. In addition, complex information about the working environment of the equipment and new design details needs to be absorbed into the software and turned into buildable assemblies, that will result in a working piece of equipment. Sikich works with Bluestar PLM. This PLM system is working in very close synchronization with D365 for F&O.

Sikich has added functionality for revision control in the Purchasing and Production module of D365. This way, the management of revisions is transparent for production and supply chain, and the risks to build or buy the wrong revision is reduced to a minimum. PLM and ERP are as close to working as one system as possible. Both “sides” have extensive insight in data from “the other side.” This means that engineers have insight in inventory and cost of items, while operations have visibility of revisions as soon as they occur so they can decide how to respond.

In addition, every ERP user has access to drawings and 3D models in Bluestar View mode, available from all relevant D365 screens. This means direct access to engineering data, which greatly helps buyers, receivers, and production personnel to be aware of the exact nature of the item they are dealing with. Each project creates new part numbers that personnel inreceiving, in purchasing, and in production have never seen before. Direct access to physical dimensions and other specs is a key advantage.

Workflow is a critical solution that connects engineers with buyers and shop floor supervisors and provides a formal Engineering change procedure. Workflow is used in the Bluestar PLM system and D365. This prevents miscommunication between engineering and operations, which could easily lead to rework or supplier returns. The use of alerts is also critical in the ETO environment. A last-minute design change can lead to a production order being put on hold, or the vendor needs to receive the latest drawing revision with urgency.

In addition to workflow, alerts are an essential tool to manage design change. Sikich recommends specific alerts to customers in ETO manufacturing.

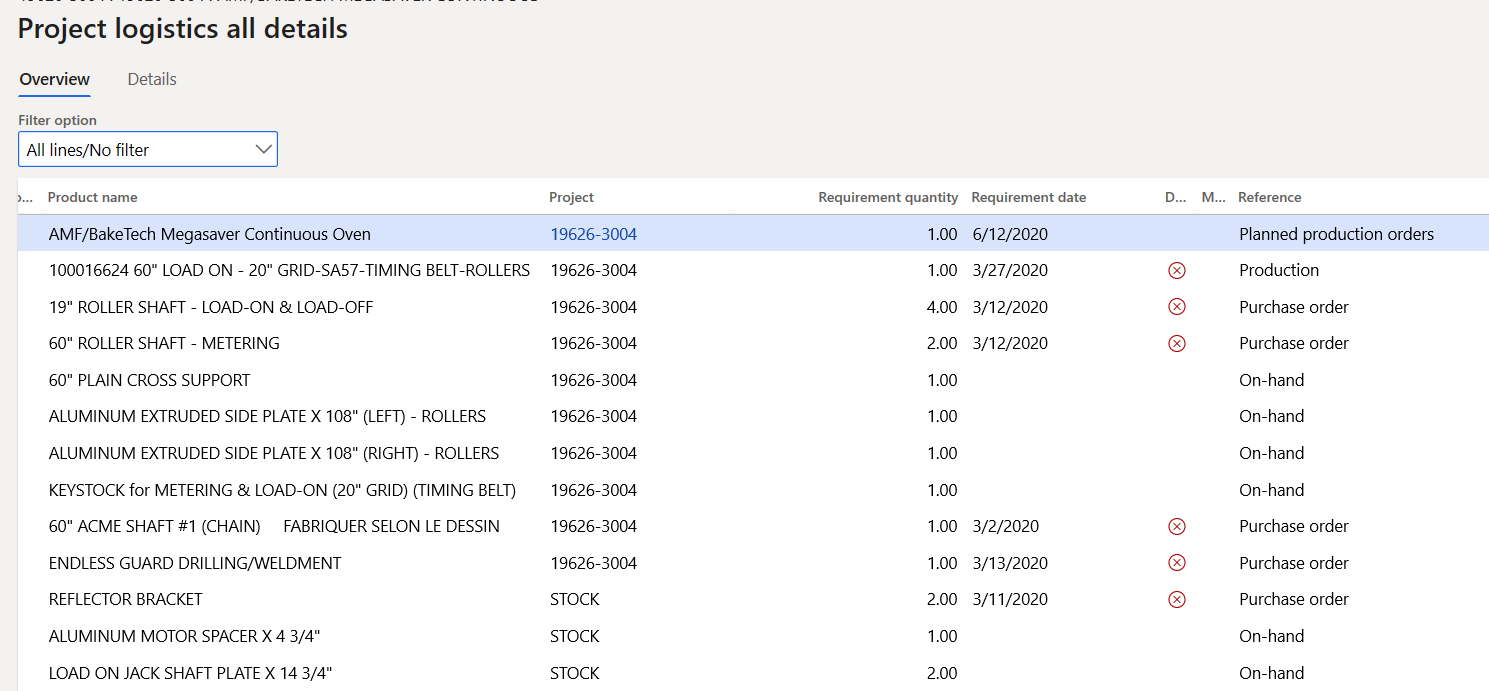

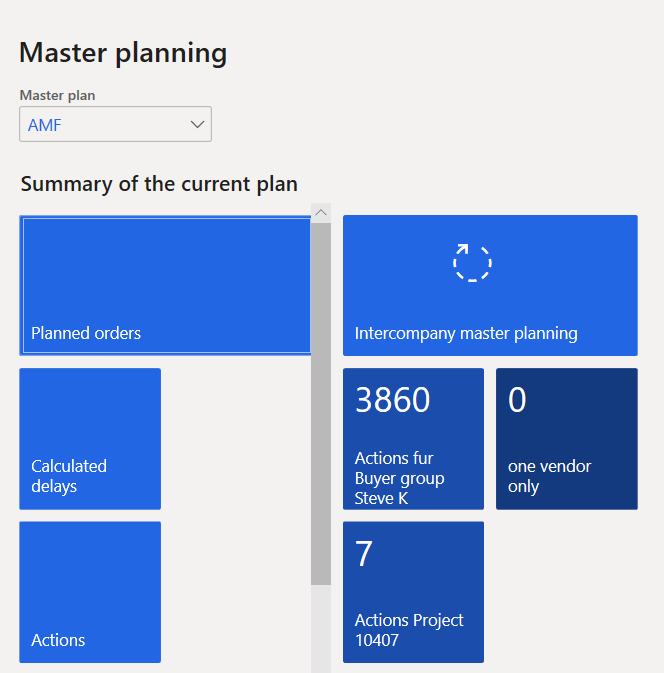

Project Requirements planning – Ad Ultima

A critical third party in the Sikich solution for Engineer-to-Order is Ulti-project from Ad Ultima. This functionality addresses the key requirement of material management in the ETO-vertical, which is project MRP. The MRP explosion of the Bills of Material is now able to plan materials for a project, which provides us with project inventory and production orders and purchase orders that are for a specific project. This segregation of material planning by project is a key requirement for this vertical. But not everything is project specific. As a product line matures, more standard solutions will be used, typically on lower BOM-levels. This will lower the overall cost. This means that in most companies, there are several “standard” parts or assemblies that are used in every project. The Ulti-project functionality combines planning for these “common parts” seamlessly with the planning of project-specific items.

The most powerful feature of Ulti-project is the project cost sheet where all project labor and material costs will show in one page, in dollar amounts, or quantities. This is a breakthrough feature for the ETO vertical. Engineering hours, project management hours both show side by side with production actual hours in , welding, assembly, steel cutting, etc. This gives the project manager instant insight into the project’s progress and its profitability.

Using PowerBI, the cost sheet can be represented graphically, providing the perfect input for the weekly project review meetings that our customers typically have.

A special mention on subcontracting is essential. Subcontracting is used widely in this type of industry. The visibility of subcontracted cost as its own category is very important. The Project cost sheet provides this without problems, whether the subcontracting is outsourced engineering design, or outsourced heat treat or anodizing.

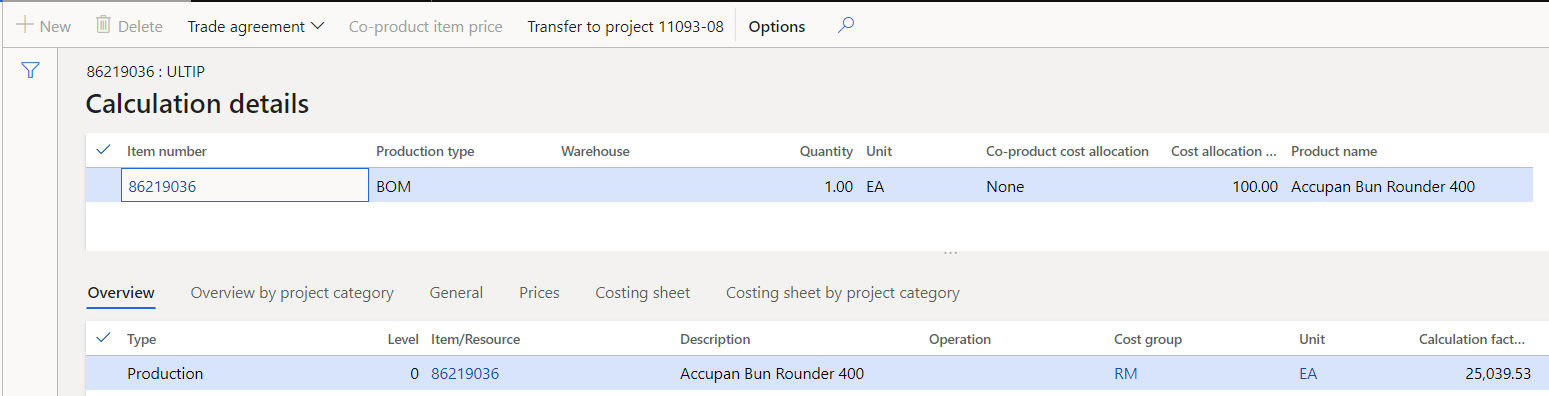

Project budget updating from the BOM calculation

The third-party Ad Ultima solution functionality provides customers with another unique feature, which is the ability to update the project budget from the item cost calculation. Typically, an equipment Bill of Material is not fully designed at the time the project structure is created and, therefore not part of the original project budget. As the BOM and sub-BOMs evolve, the estimated cost can be pulled into the project budget and, by extension, into the Ad Ultima project cost sheet. A common way to use this feature is to find a previously built equipment that is sufficiently close to the current design. BOMs and Routings of this equipment can become the basis for the project budget for the new project.

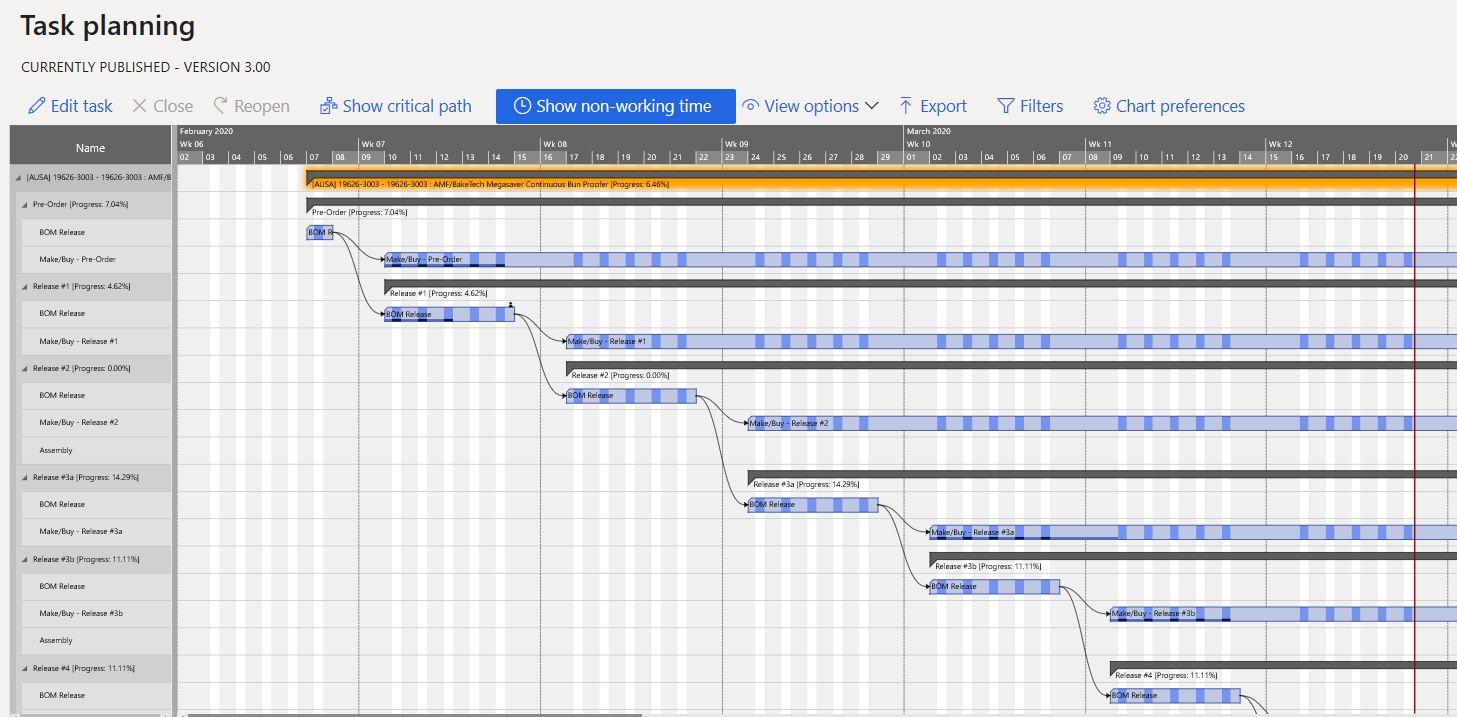

Visual Project planning – Axtension

Sikich recommends the use of Axtension Visual Project planning (VPP) to its Engineer-to-Order customers. This provides a graphical view of the Project WBS. With a graphical view of the WBS, our project manufacturing companies have a better view of milestones and can easily make changes in the plan graphically. Some Work Breakdown tasks occur in parallel. Axtension VPP has the option to use the linking types start-start, end-end that the standard system does not provide. This makes the WBS a more accurate master plan for the Project.

Production orders benefit from a special Axtension feature, and that is the colorful shortage indicator. Sikich has always provided extra functionality for production shortages. Still, with Axtension, we will get very user-friendly graphical indicators that allow our customers to make decisions on which production order to release next.. This will help with reducing WIP and keeping the factory floor from being clogged with work that cannot be completed. Also, this increases overall factory throughput, and it dramatically increases the likelihood of shipping the equipment on time!

Creative use of tiles in Workspaces

Workers at an ETO manufacturing company have a large number of data to manage every day. Examples include: New vendors have to be found, RFQs processed, machines require special setups, and the on-going design changes coming from engineering require constant attention.

The feature of prefiltered tiles provide significant benefit to our customers to handle the vast data stream, because they provide instant information regarding the workload (via the counter) and can be filtered very precisely so they only show the most relevant data or transactions (80/20 rule). When filtered tiles are combined with Ulti-project functionality from Ad Ultima, some remarkable functional features become possible, for example:

- MRP action messages per project

- Late production orders, purchase orders per project

Metrics for the Engineer-to-Order industry

Sikich is expanding existing D365 metrics, all of which are relevant for this vertical, with additional metrics that are typical for the Engineer-to-Order industry. For example:

- Engineering BOM-release on-time % (Using WBS functionality)

- Production non-conformance % per department/per project (Using non-conformances for production orders)

- Production order cost variance per department/per project

- Spare part revenue per sold equipment (using project functionality)

In the pipeline

Sikich is developing an interface between D365FO and CE Field service for automatic Customer asset creation in CE Field service based on a shipment in D365. Asset management will become part of the implementation plans, including Power BI graphics for Asset history.

Have any questions about D365 for ETO manufacturing vertical? Please reach out to one of our experts at any time!

Co-authored by Evert J. Bos and Michelle Williams

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.