This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

D365 Production Material Picking Improved for Regular Warehousing

Regular warehousing functionality is not going away in Microsoft Dynamics 365 for Finance and Operations. There are plenty of manufacturing companies that do not need Advanced warehousing. Advanced warehousing functionality for raw production order material picking gave us the idea to improve the standard functionality for regular warehousing. This customization is described below.

Production order (raw) material picking

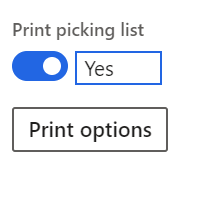

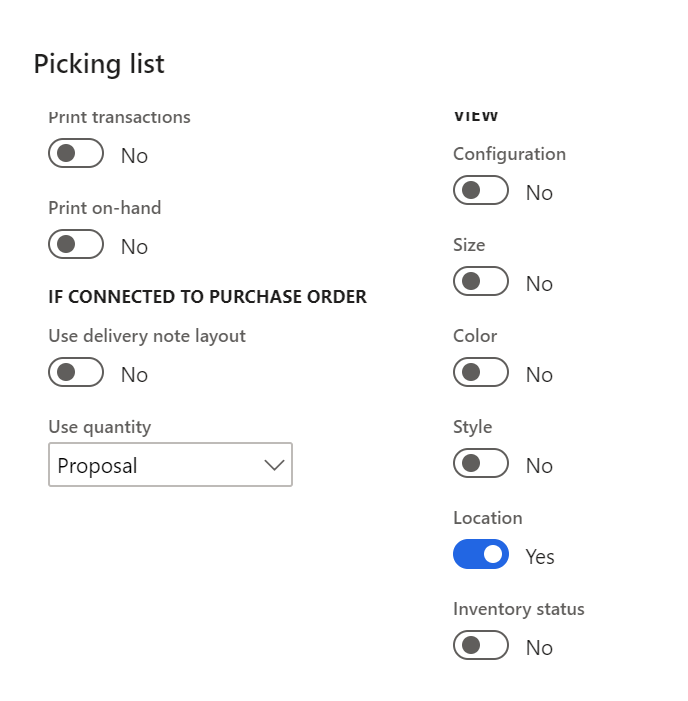

Advanced warehousing generates “picking work” that will only contain items with a physical reservation. This means that I can physically pick what shows in the picking list, because it is very likely to be there. This is a critical feature that regular warehousing misses. With regular warehousing, if I create a Picking list journal during Start of the production order, the system does not look at any reservation; it simply prints the items on the Prod-BOM. I am assuming we have indicated that the location dimension should print on our picking list using the print options from Start > General tab.

We do have an indication that an item is not available. When the location remains blank, we know that there is no physical reservation for the item and there is nothing to pick. But we want a real picking list like we have in Advanced warehousing, where items without a physical reservation do not show up on the list.

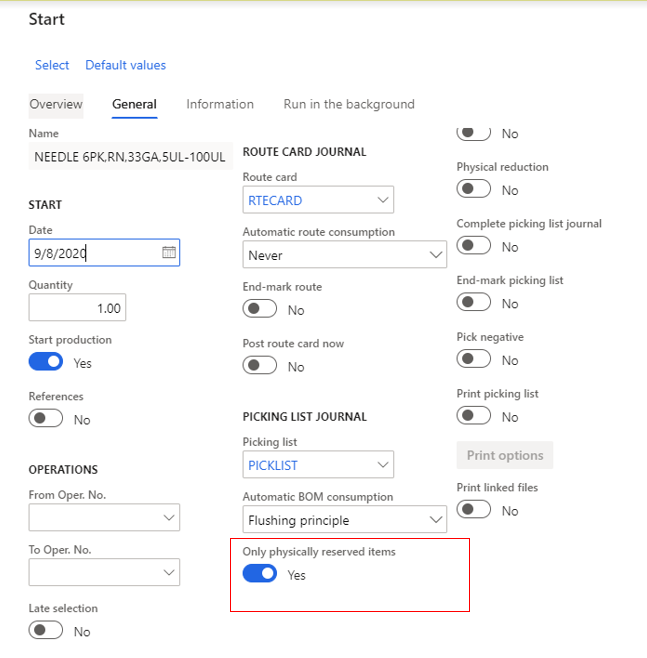

What to do? Quite simple. We added logic to the Start screen, represented by a new field “Only physically reserved items.”

Even if we reserve at the last possible moment, at Start, this will still work. The Picking list journal that is created will only contain items that have physical reservations.

Picking list when production order materials arrive

But how does the story continue when we typically do not have all items available when the production order starts? What happens when these materials arrive? I will need another picklist journal for them.

In Advanced warehousing we can “release to warehouse” repeatedly. When late items arrive and they are physically reserved, we need to create additional picking work.

The same thing is possible with regular warehousing, and it does not require any customization.

We simply start the order again, with zero quantity (the default), in batch.

When items are received that are needed for a started production order, they will physically reserve if we have marking in place. If there is no marking, we have to find another way to create the physical reservation.

The batch program to “start” the order again will have this new parameter: “Only physically reserved items” set to “Yes.” The system will find new items with reservations and will put them in a new picking list journal.

NOTE: This solution requires you have the reservation parameter for Production orders at “Start.”

This journal can be printed automatically or appear under a tile for the user to print. Either way, we are in business. Incremental pick lists are generated based on recent physical reservations. We can do as many additional picks as needed for this one production order.

This puts the regular warehousing functionality for production order material picking on a better footing.

Remember that we are not advocating the use of the “picked” status for Prod-BOM lines. This would create extra manual effort without any gain in the business process. Typically, with regular warehousing and production, our inventory transaction for each Prod-BOM lines goes right from “physical reserved” to “deducted.”

Conclusion

Regular warehousing has been generating production order material picking lists without checking for physical reservations for as long as the system has existed. This is a problem in real business, and it is rather simple to fix via the customization described above, but you need to have reservation “at Start.”

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.