Version information:

The quality management feature we demonstrate here was added to Microsoft Dynamics 365 Finance and Operations (D365FO) March 2020 and enabled on June 11.

The official documentation is remarkably detailed.

D365FO Quality Management Functionality in Summary

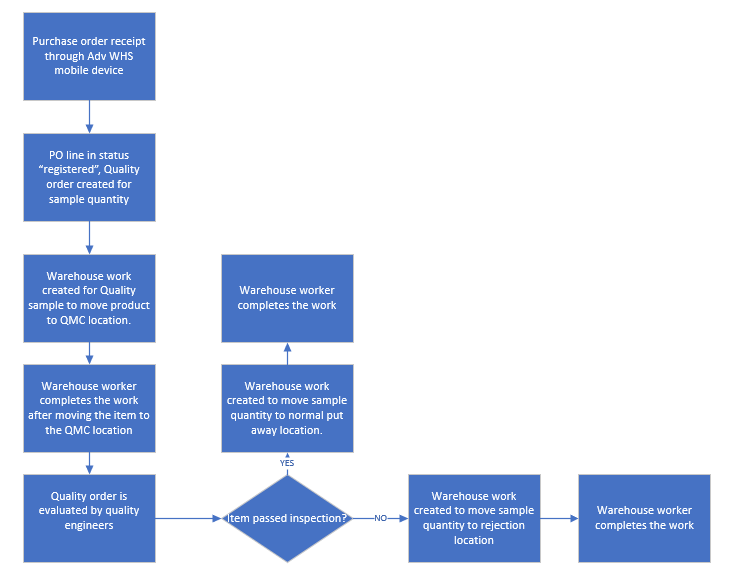

The new D365FO quality management feature allows for the test sample of items to be moved to a special location for quality inspection, and after testing of the items is completed, the test items are moved to a location that corresponds with the outcome of the quality test and the evaluation of the quality order. Quality orders and advanced warehousing were able to work together since Advanced Warehousing came out. We could change the inventory status of the tested sample quantity during the evaluation of the Quality order. This feature, however, is much better as it gives us the functionality of the Quarantine order back! All customers I know want to have inventory to be located in special warehouse locations during and after quality inspection. This mirrors what happens in the real world. Quality testing is done on special locations and non-conforming products are moved to a special location.

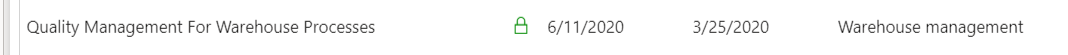

Setup of the Warehouse

This parameter Enable quality orders for warehouse processes has to be enabled on the warehouse.

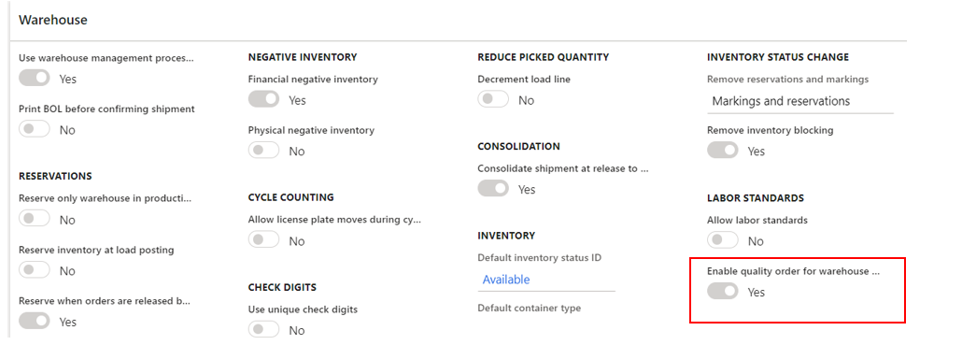

Setup Quality Associations

Above, is an example of a Purchase order quality association. The new value “Quality management for warehouse processes only” in Applicable warehouse type field is new and is only available when Event type is set to “Registration.” All warehouses in site 2 that have the new field for quality enabled will be eligible for this quality association and a quality order will be generated after the status “Registered” on the PO line has been reached.

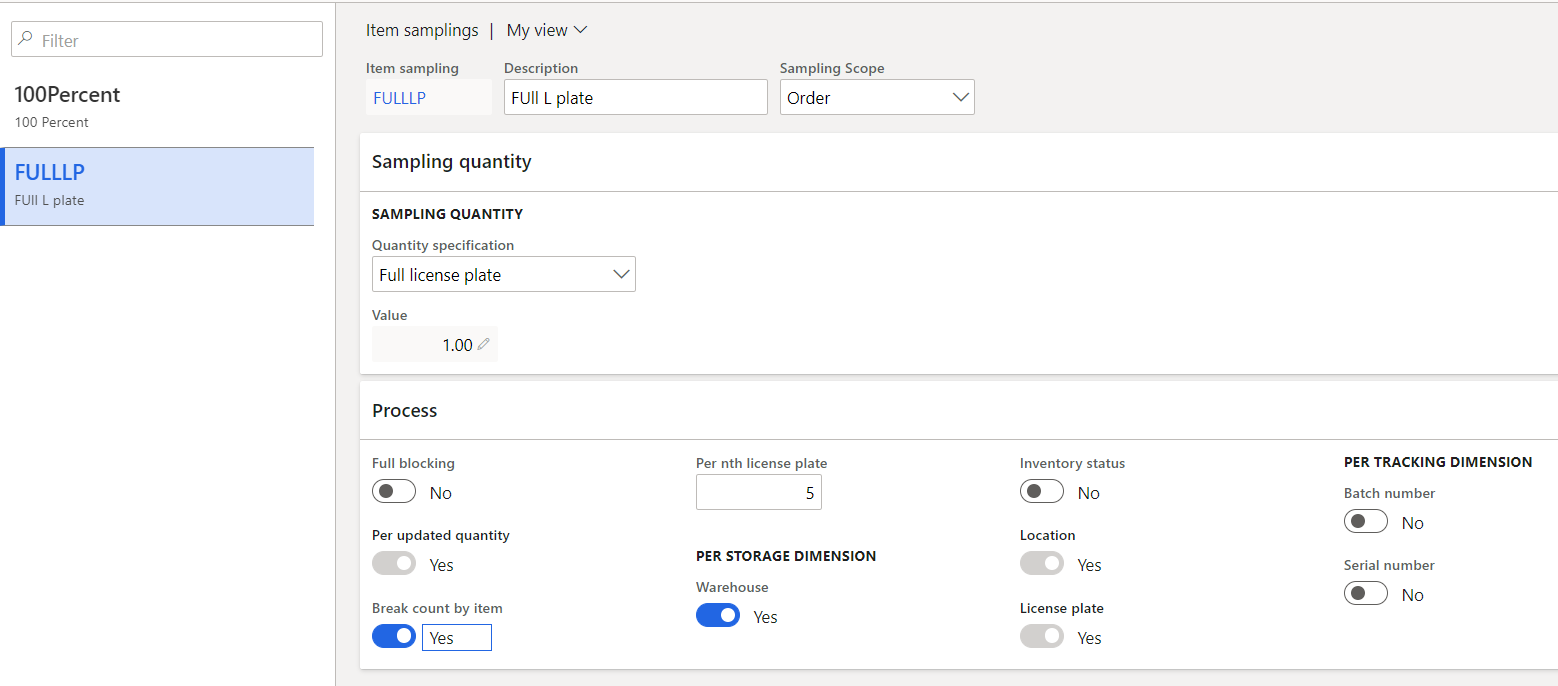

Setup Item Sampling

The Sampling scope is defaulted to “Order” (other values are “Load” and “Shipment”). For purchase order quality inspection “Order” is the only usable value.

Our goal is to block the entire quantity that we receive on the PO line.

We set Quantity specification to the new value “Full license plate.” This value also makes it possible to use a new field Per nth license plate. This is really good news. We have been waiting for a “skip lot” feature where we only want to inspect every “nth” Purchase order and this gets us very close.

The value “full blocking” is no longer possible with this new feature, but our “full license plate” gives us the 100% sample size which will of course be 100% blocked.

Break count by item is a critical parameter that works with Per nth license plate. With Break count by item set to “Yes,” it will keep count “per item.” We are going to get a quality order for every fifth license plate for a specific item. With Break count by item set to “No,” our count is on all items, which makes no sense for Quality management. We need to keep track of our inspection results by item if we want to manage our inspection frequency and become more lenient or more strict, dependent on the quality we are measuring.

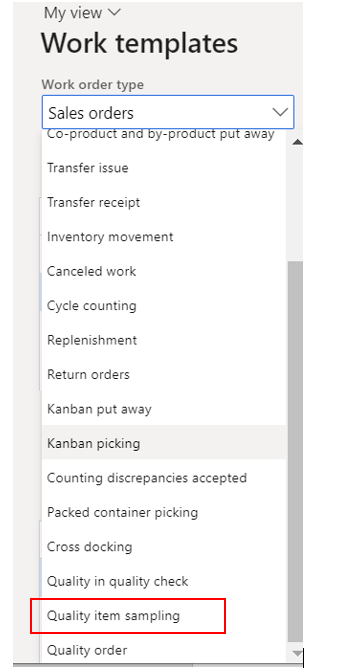

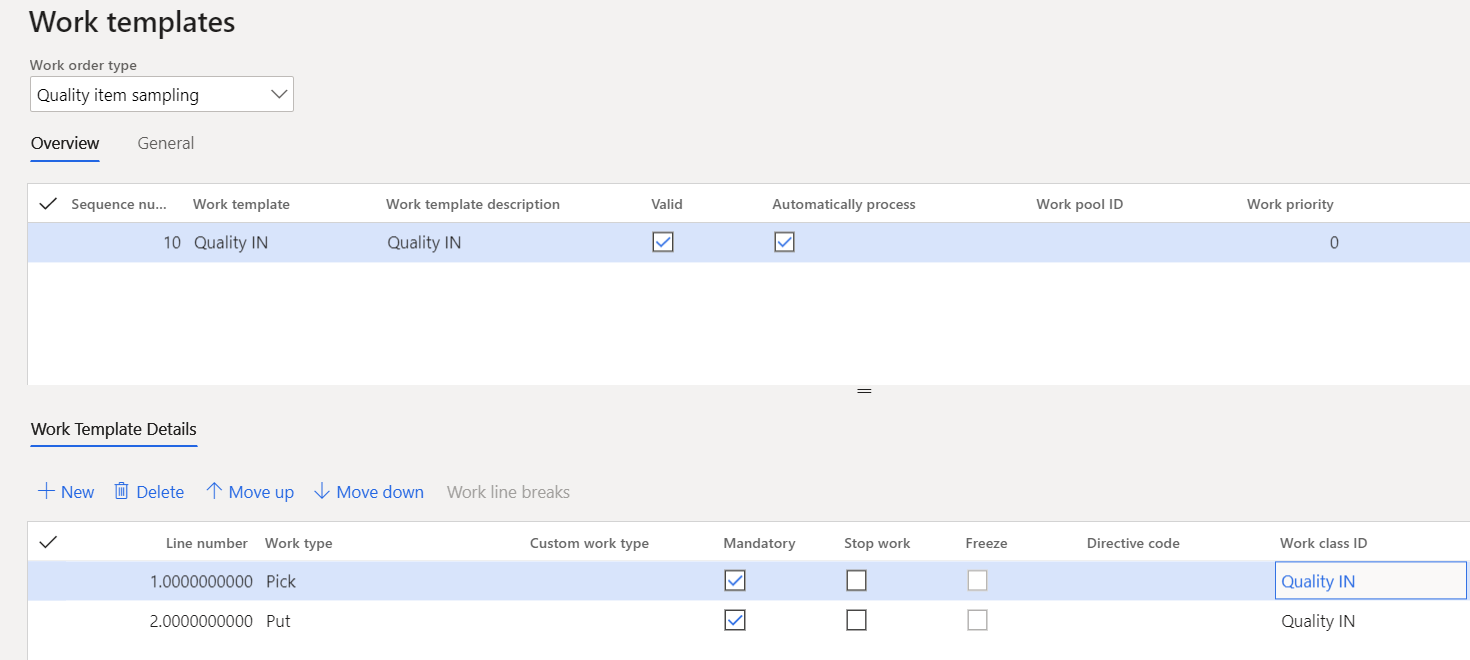

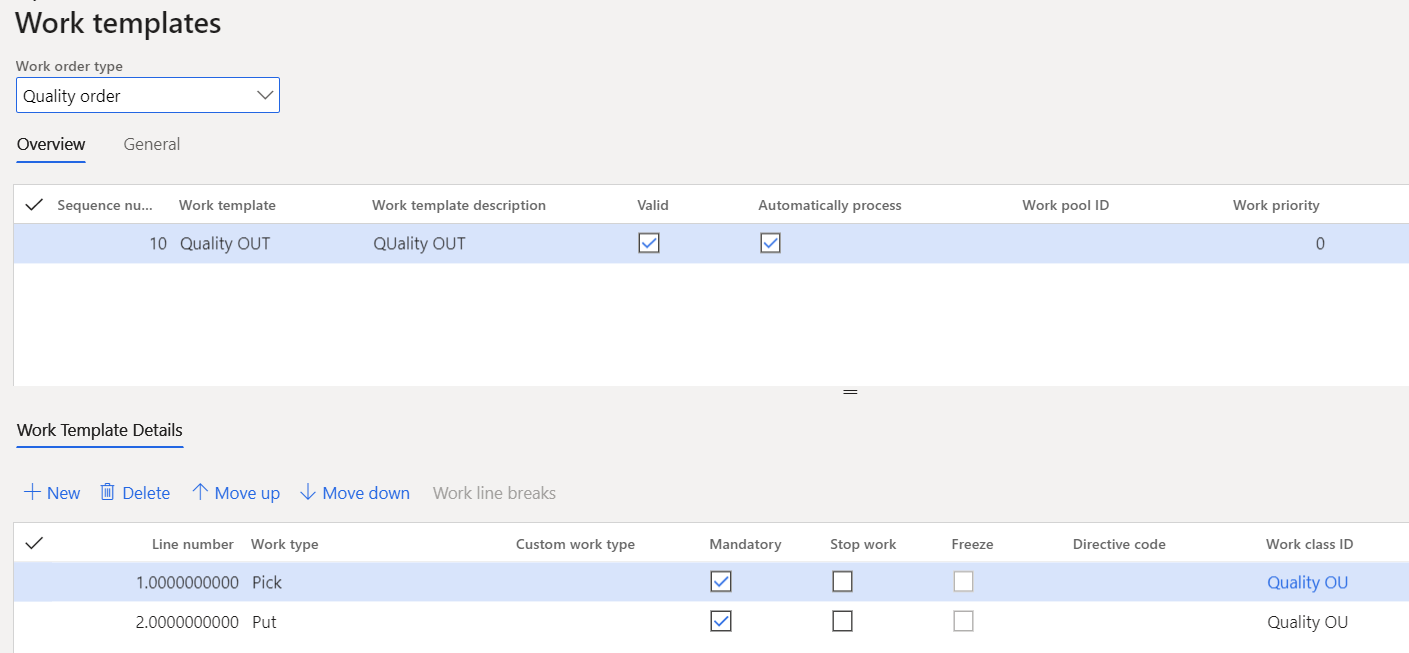

Setup Work Templates

There are three new work templates! The first one, “Quality in quality check,” is about a different feature, the so called “Quality spot check.”

“Quality item sampling” is about creating warehouse work to move a to-be-inspected quantity, which is in fact just a registered PO line, to a special quality location in order to perform inspection.

We call it “Quality IN” and there is nothing special about this work template. We use a new work class ID that is using the same work order type “Quality item sampling.” No query needed.

This is the order work template, we call it “Quality OUT.” This will create the work after we have finished the inspection and evaluate the Quality order. This work moves the quantity out of the inspection location to a destination location that depends on the outcome “Pass” or “Fail” from the Quality order. No query needed.

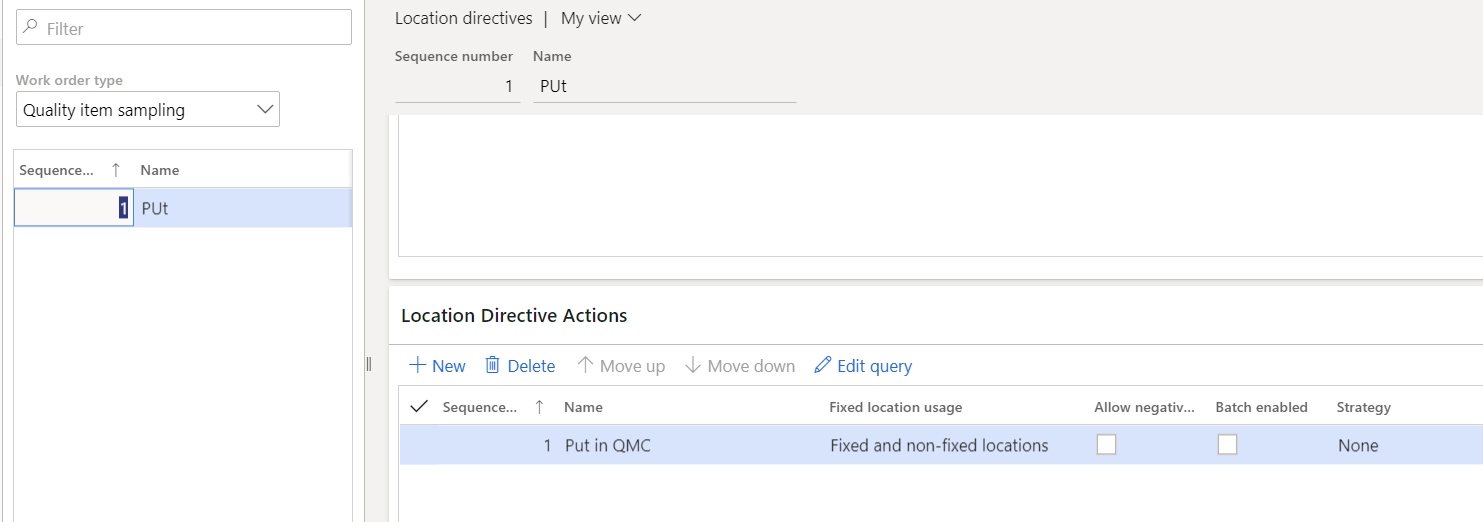

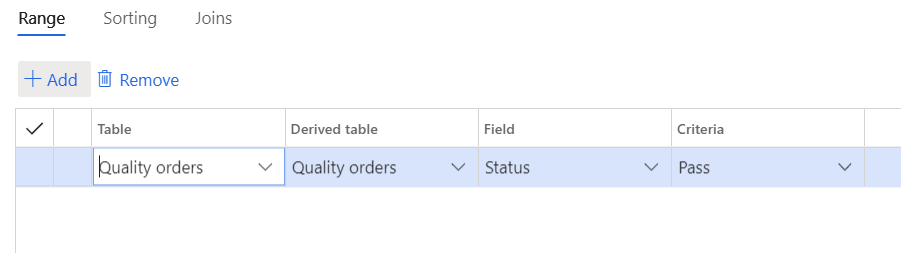

Setup Location Directives

This location directive is needed for the sample quantity and is only a “Put.” The destination location is defined in the query for the bottom section of the directive shown here.

Our sample quantity will go to QMC location and sit there while we perform the tests of the quality order.

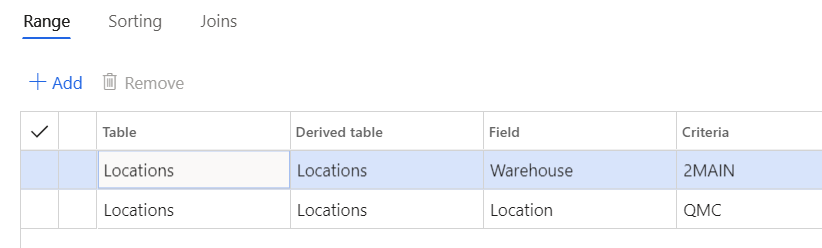

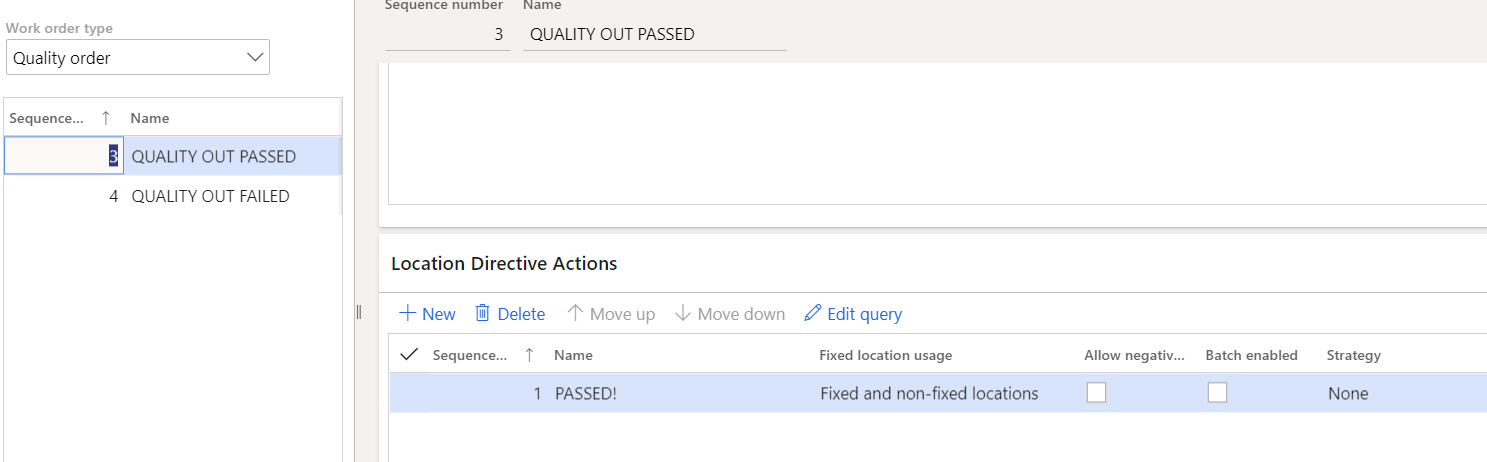

There are two directives for the Quality OUT situation. They are both a put.

The query below connects to the outcome of the Quality order:

The query below indicates the location where the item should go to:

This completes the setup.

Test the Process

The Quality Order

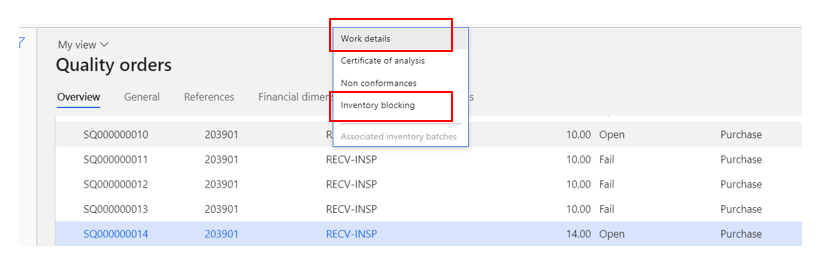

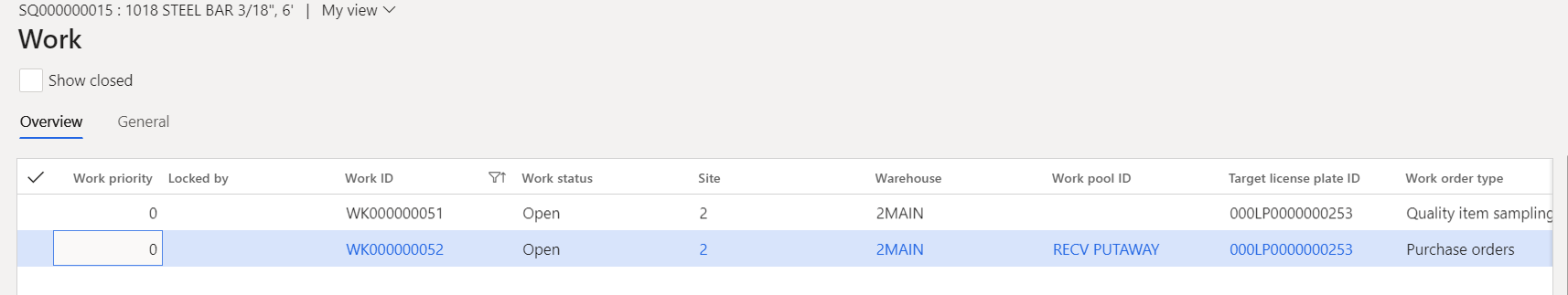

We have our first quality order for this item. The next four license plates for this item we will NOT get a quality order because our Purchase order Quality association says, “every 5th license plate.”

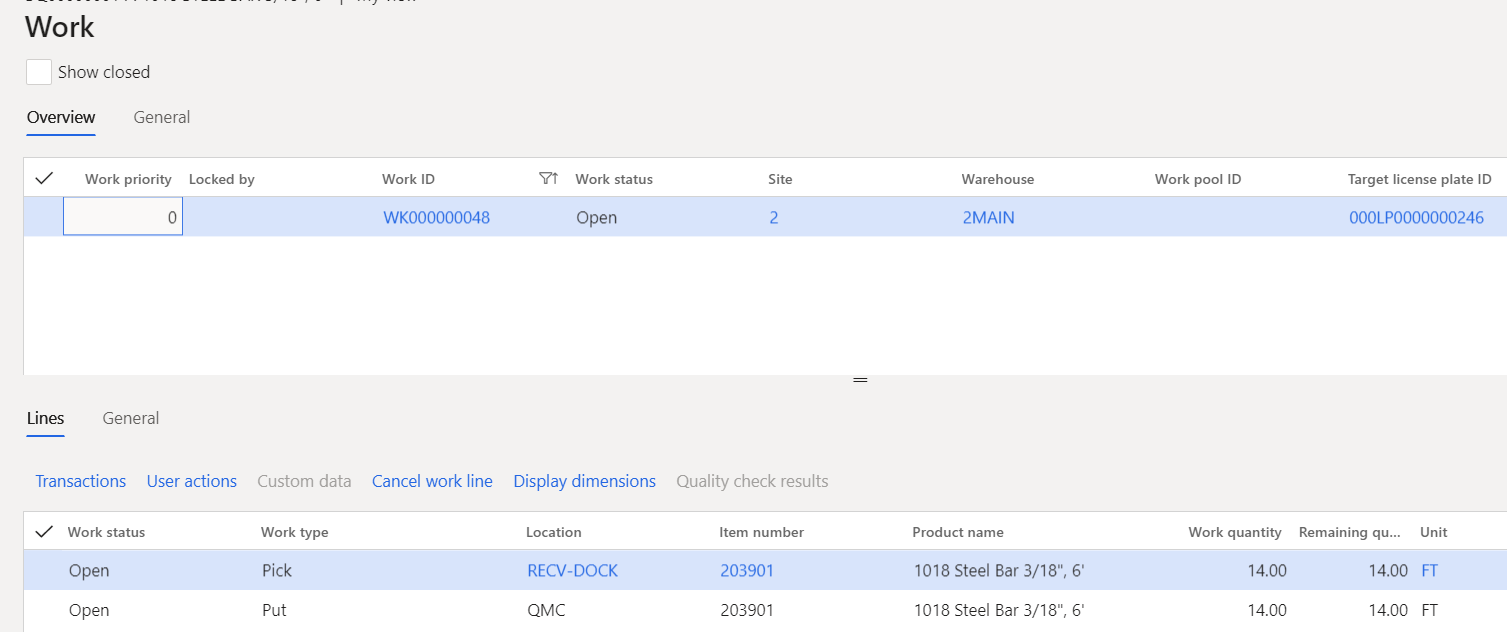

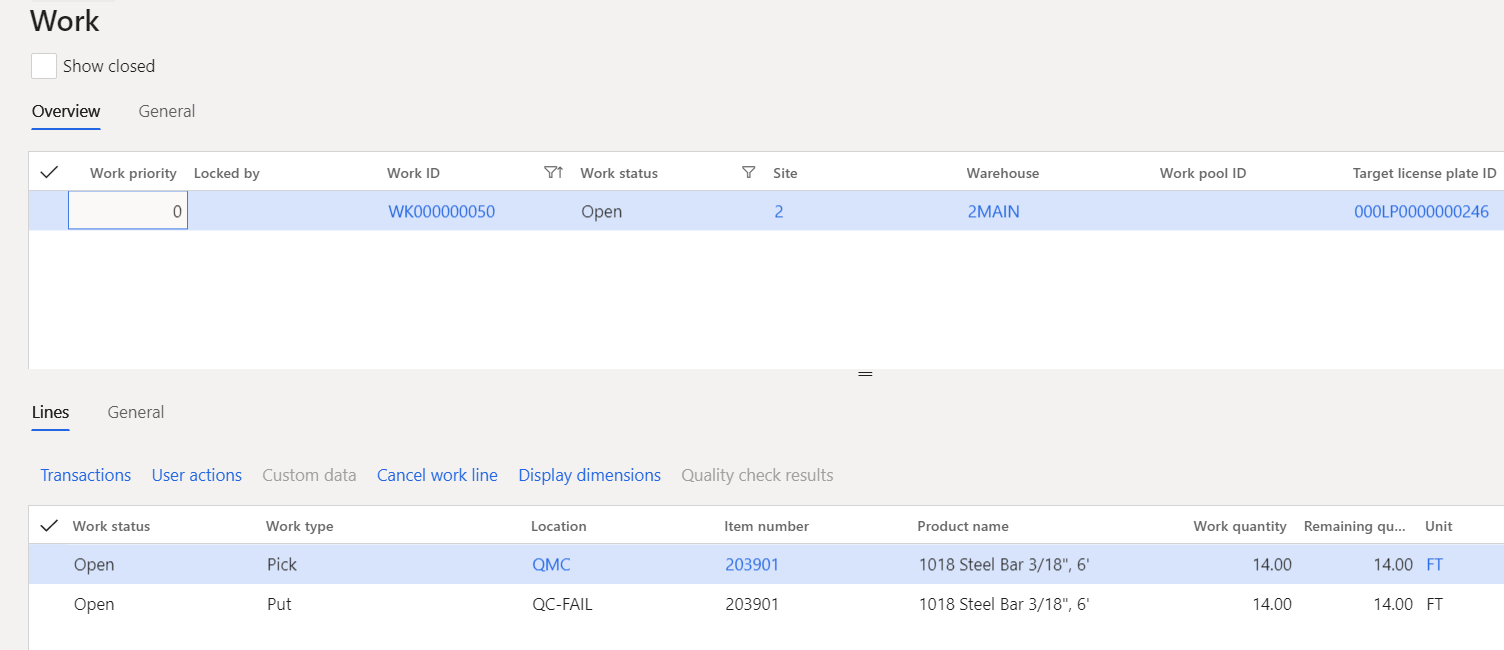

The work details on the Quality order show the warehouse work that brought the sample size to the quality inspection location. Our Purchase order line was for 14.

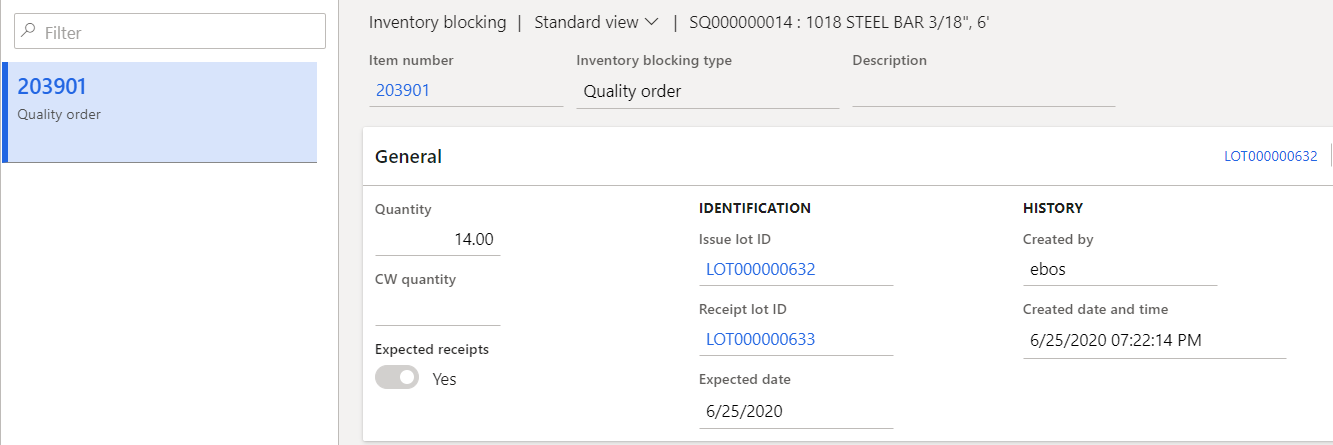

The Quality order quantity is blocked and that can be seen in Inventory blocking.

After we evaluate the quality order, work is generated. This work is not shown under the pull down menu of the Quality order but only in “All work.”

In our case, we had a fail. This work will put the quantity in a QC-Fail location, where it will be awaiting further action.

What About Production?

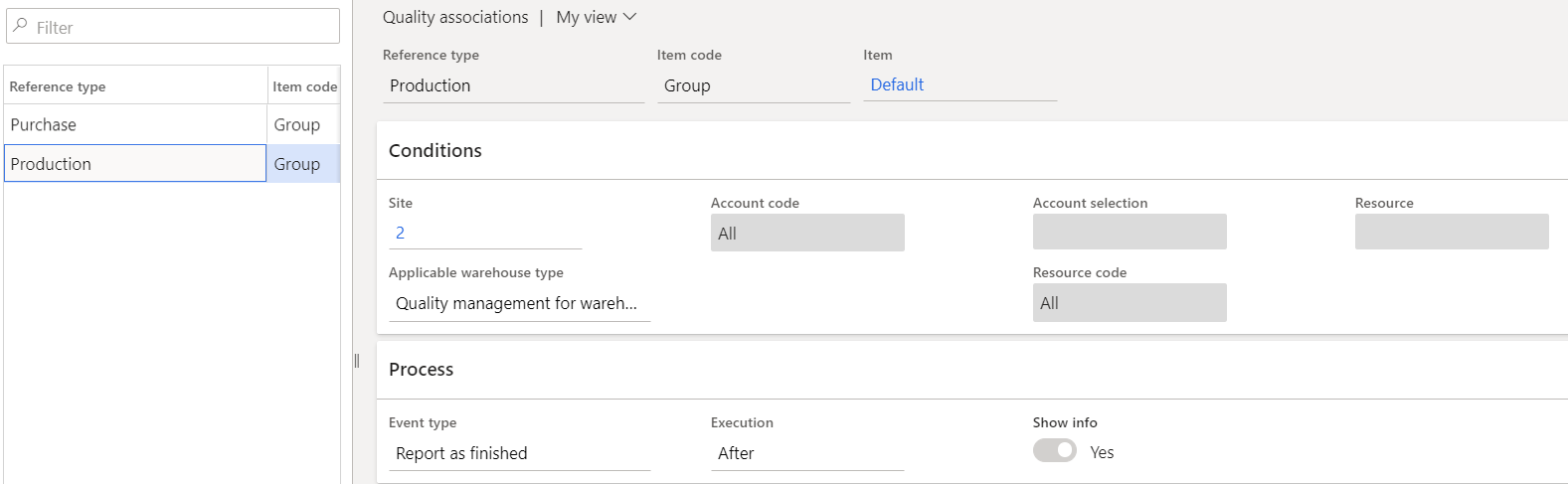

For production the quality association requires event type “Report as finished.” The process is identical otherwise.

Conclusion

This is a very valuable enhancement that fits the requirements of many customers much better than the use of “Inventory status.” It brings back the functionality of the Quarantine order but now on the location level!

What we would want to see changed is the behavior of the system when we use a sample size less then 100%. When the test leads to a fail, the entire quantity should be moved to a special location, not just the sample size. Especially the “every nth license plate” feature is highly appreciated as we are getting the “skip lot” question very often.

The example above is what happens when I have an item sample of 10%. I get two types of work. With a PO line quantity of 100, I get normal put away work for 90, and I get quality item sampling work for 10. If I have a “pass,” no problem. But if I have a rejection, those 90 are in the wrong location! I have to get those 90 out of the regular location to the rejection location. We hope this will be changed.

Have any questions about D365FO quality management with warehouse processes? Please contact our experts at any time.

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.