In Sikich’s 2019 M&D Report, our team gathered findings on challenges and trends in the industry and how your peers approach change to create opportunities for their businesses.

At the end of last month, I had the opportunity to gather with local leading manufacturing and distribution experts to discuss Sikich’s 2019 M&D Report findings. With 2020 right around the corner, I was eager to get an insider’s perspective into the economic outlook of the manufacturing industry. While the fall season can be slow for manufacturers, very few of the industry leaders I met with expressed concern of a slowdown in their business and its profits. According to my colleagues, the past year has delivered success in revenue and growth—and expectations for 2020 are high. Let’s dive into that.

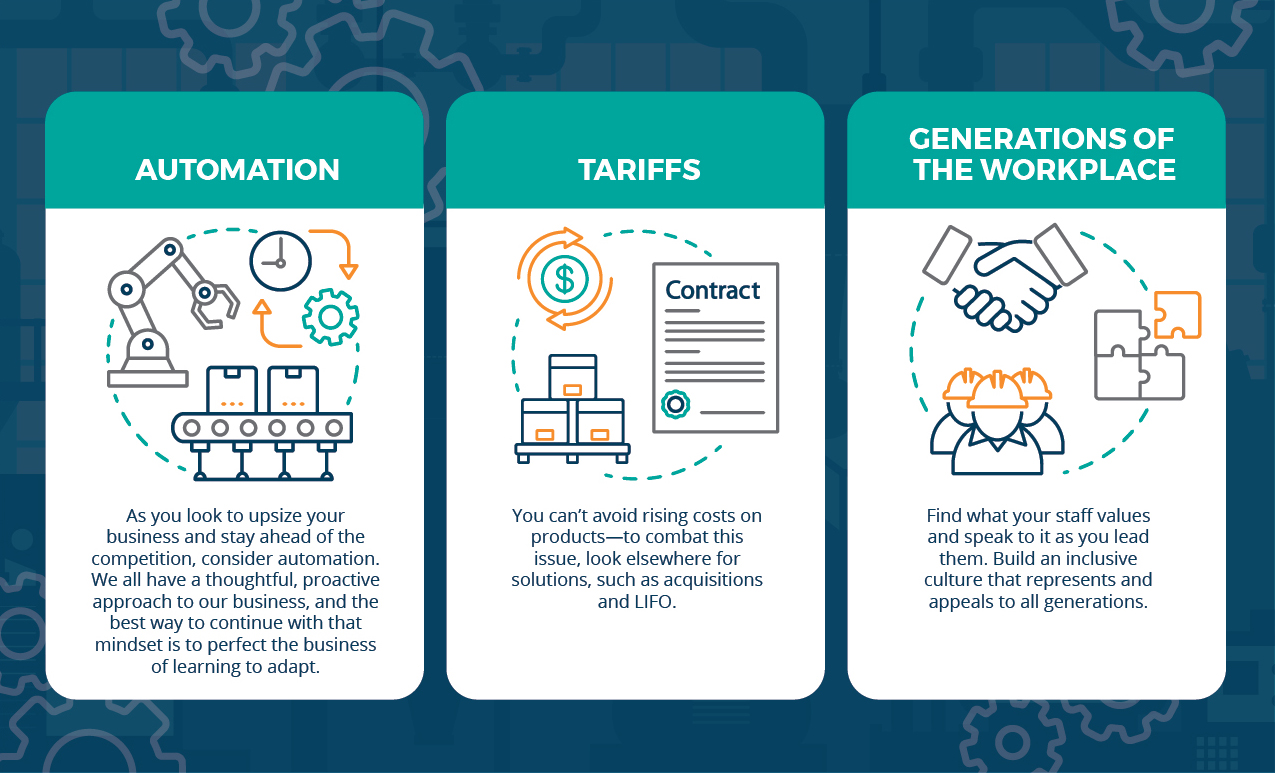

Automation: Learn to Adapt

The conversation of automation was a recurring topic as I discussed what the future holds for leaders in this profession. As manufacturers strive to differentiate themselves in the war for talent and consumers, business owners are relying on automation to drive success. For this to work, manufacturers need to find the right balance between automation and integration. Robotic process automation (RPA) cannot be successful when processes aren’t put into place or when skilled staff are not leading the charge. RPA “co-bots” cannot make decisions, think for itself, or pick up on skills without first being taught. Robotics is often most successful when used for high-volume, back-office tasks.

Before bringing automation to a production floor, business owners need to bridge the knowledge gap. This can be done by hiring new staff that are trained in robotics and capable of implementing processes and monitoring success, or it can occur by training your staff on the technology. When applying new procedures and technologies, the success of the system depends on the support and involvement company-wide.

Automation is certainly an investment, and you’d be advised to be wary of low-cost providers. However, Research & Development (R&D) government tax incentives offer financial resources to manufacturing companies that choose to employ automation in their factories. Companies that implement a new automated process or improve efficiencies through AI technology can apply to receive tax credits that cover a considerable amount of their costs.

Final thoughts: As you look to upsize your business and stay ahead of the competition, consider automation. We all have a thoughtful, proactive approach to our business, and the best way to continue with that mindset is to perfect the business of learning to adapt.

The Effect of Tariffs and Next Steps

Tariffs on certain imported steel and aluminum have sent product costs skyrocketing for some manufacturers. The effect of tariffs presents itself as increased prices from suppliers, despite the purchased products having no tariff implications. In addition to wage inflation, sales and costs are up to compensate for the tariff burden.

The industry leaders I met with proposed a few business strategies to make up for the loss resulting from this industry-wide challenge. Some manufacturers are looking to diversify their business to make up for any gap in sales; they are doing so through acquisitions into new business areas. These M&D leaders are branching out to acquire businesses in new and different industries, such as medical, biotech, and industrial. These industries are leading an upward streak of success, and manufacturers are seeing this as an opportunity to diversify.

Other manufacturing professionals have adopted the “Last In – First Out” (“LIFO”) inventory valuation method. The LIFO inventory method assumes that the most recently purchased items are sold first. As a result, the inflationary impact of the inventory is removed from the inventory on the balance sheet and currently deducted from taxable income. Instead, the inflation is recorded as an inventory reserve, which continues to grow year after year as the impact of inflation on the product costs continue.

LIFO allows businesses to deduct the most recent costs of purchased inventory against their current sales. It matches current sales with current costs of those sales. If inflation is producing rising product costs, the cost of goods sold is increased under LIFO, which creates a higher cost of goods sold deduction and a lower taxable income. In effect, this tax benefit is an “interest-free loan.”

Final thoughts: You can’t avoid rising costs on products—to combat this issue, look elsewhere for solutions, such as acquisitions and LIFO.

Generations of the Workplace

Today’s workforce is a blend of baby boomers, millennials, and more—and it will only continue to become more diverse in the coming year. I discussed with leaders in the industry how they find what each generation values and how they tailor their management approach accordingly. To start, an employee’s goals need to be identified. Their goals are likely to reflect their age; for example, a millennial worker may want increased learning opportunities in their career.

Once those goals are identified, make sure you’re meeting those expectations and helping your staff to reach them. Spend time on the production floor, listening to your team and encouraging them to learn and grow. Find your employees’ strengths and develop those attributes.

When introducing new software and technology, remember that different generations have diverse experience with advanced technology. Make sure the implementation of these programs isn’t intimidating and that you spend time training your team. Tailor your processes to your audience. Gen Z, or generations coming straight from high school or a post-secondary education, are likely to have a firm grasp on AI and other technologies—they will normally need less hands-on training than older generations.

Final thoughts: Find what your staff values and speak to it as you lead them. Build an inclusive culture that represents and appeals to all generations.

To learn more or to become a part of these M&D focused conversations, please contact us.

Last time, I talked with industry leaders about labor challenges in the manufacturing and distribution industry. To learn more about our conversation and how it applies to your business, read this insight.

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.