Less than ten years after its inception in Germany, Industry 4.0 has not yet transitioned from mostly large and well-resourced early adopters into the broader field of manufacturing. For high-tech manufacturers without the budgets and access to technical innovation that the largest enterprises enjoy, Industry 4.0 and its vision of digital transformation may remain abstract. While some industry leaders have published remarkable breakthroughs in using digital resources and data to become more competitive and sharpen their focus on customers, these are individual achievements. They haven’t yielded easily repeatable models and blueprints for the smaller high-tech companies. Company leaders and analysts alike are generally cautious and highly aware of the risks and investments associated with comprehensive transformative initiatives.

At the same time, many customers of high-tech companies are looking for products that more effectively support their goals for growth and profitability, or that help them create a competitive differentiation with their own customers. They may appreciate that the high-tech manufacturers with which they may have long-standing relationships are risk-averse and already may be stretching their budgets and resources to the utmost, but they are also looking for more individual and innovative approaches to product design, production, and servicing. If they find that manufacturers lag behind competitors, they may be more inclined to give different high-tech providers the chance to win their business.

At the Source of Value

If high-tech manufacturers don’t want to miss out on Industry 4.0, they need to find a way to adapt it to the way they work and how they aim to satisfy and retain customers. They can use their existing assets—including customer and supplier relationships, production processes and facilities, and data—to accomplish well-planned, low-risk, transformative outcomes. A sound guiding principle for this might be orienting the company with all of its activities to focus exclusively on creating value for customers, and discarding or re-creating any effort that does not align with this intent.

Instead of investing in production capacity and equipment to make more of the same products in the same way, a high-tech manufacturer could allocate a fraction of that planned expenditure to incremental, practical Industry 4.0 initiatives. For example, a better understanding of customers might prompt feature enhancements or greater customization in product design. Some of the data needed to drive this effort may already be in the company’s systems, from where it can be extracted in order to be analyzed.

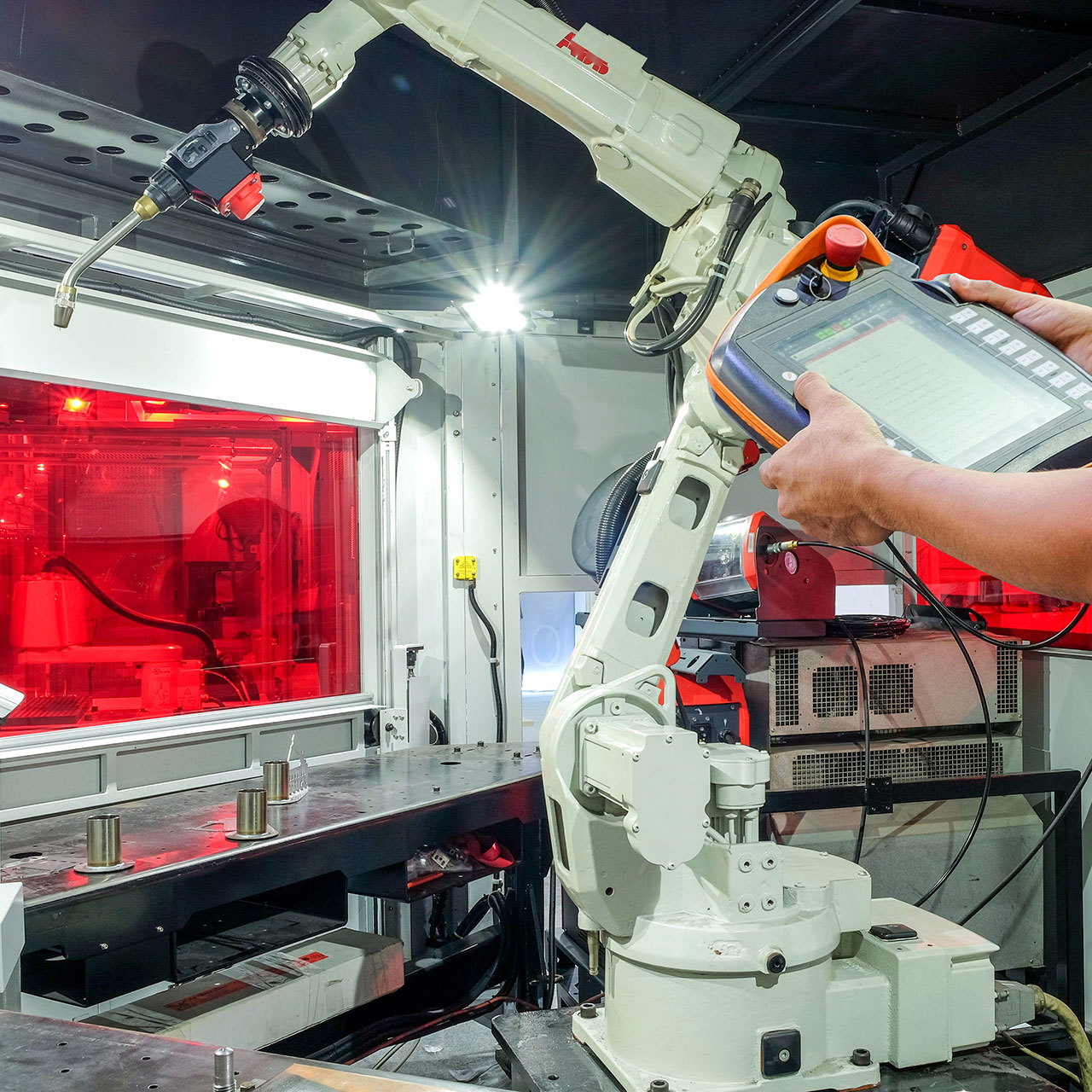

Creating true closeness with customers, no matter where they are, may require a new platform for seamless, secure communication and collaborative product design. Associating tangible metrics with this technology, such as revenue or customer satisfaction and retention projections, would probably not be difficult. With those parameters in hand, you could review technology solutions to facilitate the effort and start planning a proof-of concept to validate the approach. Potentially revolutionary and much publicized technologies like additive manufacturing or 3D-printing, or connected sensors in the internet of things (IoT) on your products and equipment, might come next if your customers and bottom line could predictably benefit from them.

Introducing Supply Chain Intelligence

For some high-tech manufacturers, transforming the company with a focus on creating customer value might not focus directly or exclusively on customer goals and relationships, but on managing the supply chain. If you have to rely on components and materials that become part of the product you make, the quality, timeliness, and cost-efficiency of your providers can help you grow or keep you back. Maybe it’s time to review suppliers’ performance and how it impacts your business, using data that you may already have together with findings yet to be collected.

Relatively minor improvements in suppliers’ product quality, delivery schedules, or prices could help you broaden your margins, use production facilities more efficiently, or pass quality improvements and savings on to customers. The assessment and reporting tools needed for this, and a communication and collaboration platform to work with suppliers anywhere, might not require a large investment to acquire or a huge effort to implement. But the results could be transformative for your company’s standing with customers.

Transformative Expertise and Low-Risk Solutions

Sikich industry and technology experts share the generally cautious, results-focused mind set of many high-tech manufacturers. In our experience, Industry 4.0 does not need to remain the privilege of the largest, wealthiest organizations. However, it takes sound fact-gathering to determine which efforts have the greatest transformative potential and identify the tools and practices that allow you to realize them at a reasonable investment, with low risk, and without wasting time. Business management solutions like Microsoft Dynamics 365 for Finance and Operations, together with the analytics and industry-specific resources you can find on the Azure cloud platform, can keep your Industry 4.0 initiative efficient and manageable, and we can help you direct it for the results you want to achieve.

Have any questions about Industry 4.0? Please contact us at any time about how we can help your manufacturing business implement Industry 4.0.

Read the Series

Be sure to catch the rest of the series!