Software version used:

Content is valid for all older versions

The safety margin or safety time in Dynamics 365 for Finance and Operations changes the requirement date of planned orders in some cases. This is a feature that has to be used with care because the user that is trying to understand what the Net requirement screen is showing can easily get confused, because the dates are not immediately understandable.

The legitimate business purpose for this feature is to provide a time buffer that the business process needs for some reason. A classic example that I have seen used in actual implementations is the inspection time for incoming purchased material. We don’t want to put extra days in the supplier lead time, which would defeat the purpose (the supplier would “use” our buffer), but we need an internal buffer for this inspection time. We wish that the PO would arrive somewhat earlier then the date it is actually needed.

There are three types of master planning safety margins, and it is strongly recommended to only use one of them because they “build” on each other, obviously.

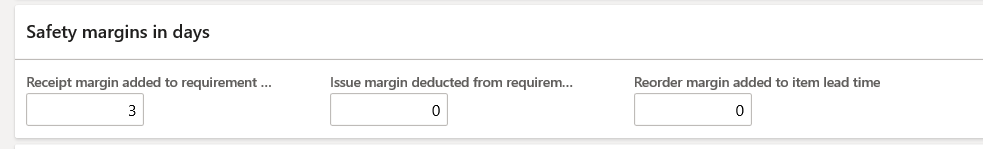

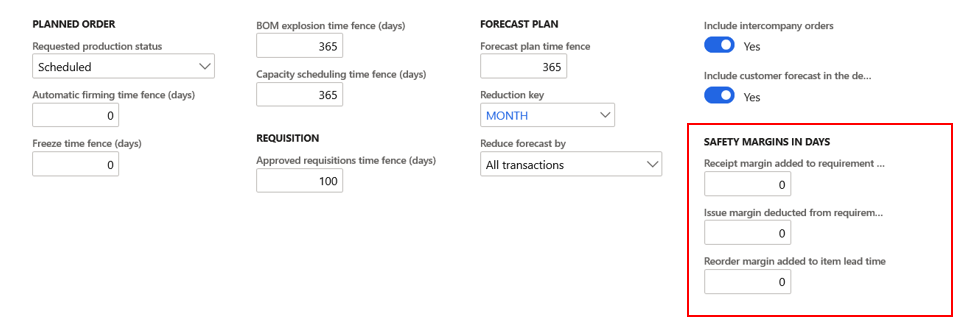

The three fields exist on the Master plan:

And the same fields are on the Coverage group:

The values on the Coverage group and the Master plan are cumulating. I found this very strange, and in all those years, I have never found a real-life situation where you would want this. The cumulation is a surprise as we are used to the Coverage group, by choice, being the lead for many critical master planning fields. For other fields, we can make the Master plan the lead.

In this case, we have no such choice. Nobody would ever want accumulated safety margins. So, this is not so much a feature but a potential problem.

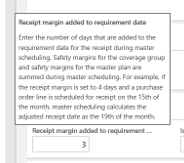

The help text on the three safety margin fields mentions this cumulation as almost the most important feature. However, the help text should be read as a warning, and we have to avoid this cumulation. Putting a safety margin on the Coverage group would make more sense so that you can be selective, and only certain items need to have this ‘buffer.’ Still, it will be hard to remember for the master planning user which Coverage group has safety time and which ones do not. When trying to understand “net requirements,” we have to know. But the Net requirements screen does not display the safety margin values at the top of the screen, so when looking at requirement dates in the bottom, I have no idea if safety margins are involved or not. That is why I think it is better to use the safety margins on the Master plan.

Safety margins can be in working days or not. This parameter is on the Master Planning parameters.

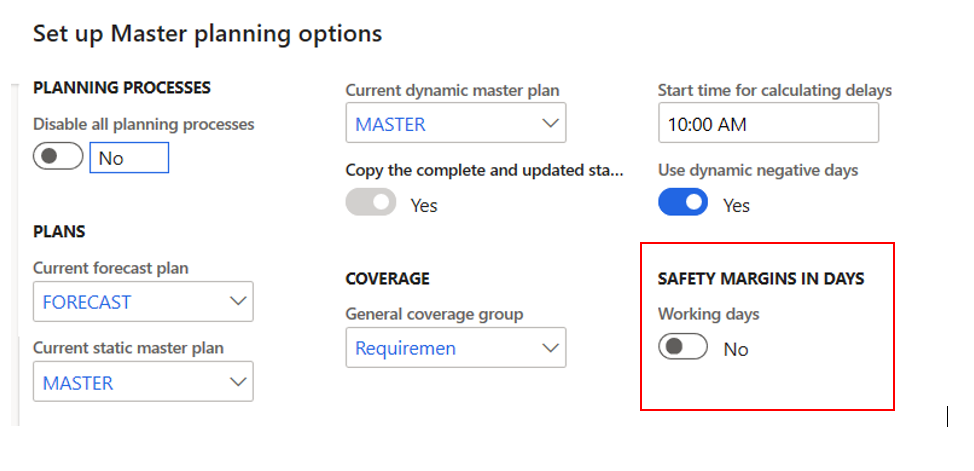

Master Planning Safety Margins TEST 1: Receipt margin of 3 calendar days

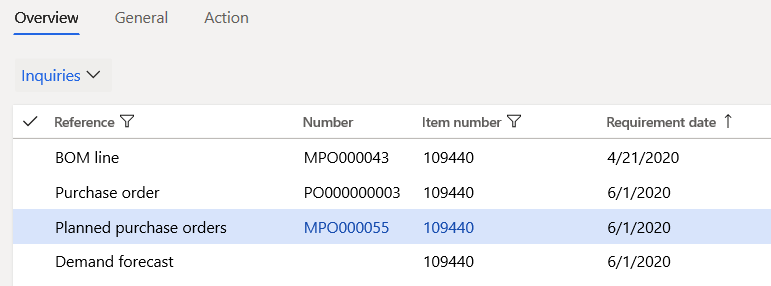

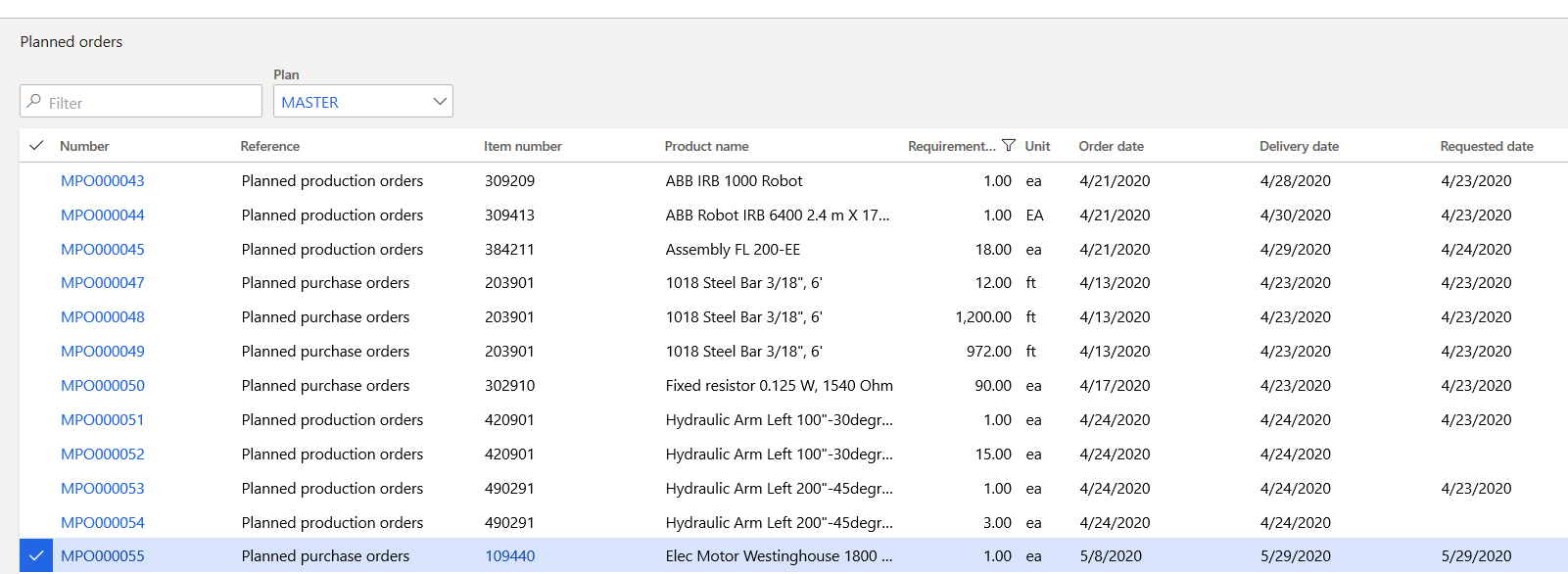

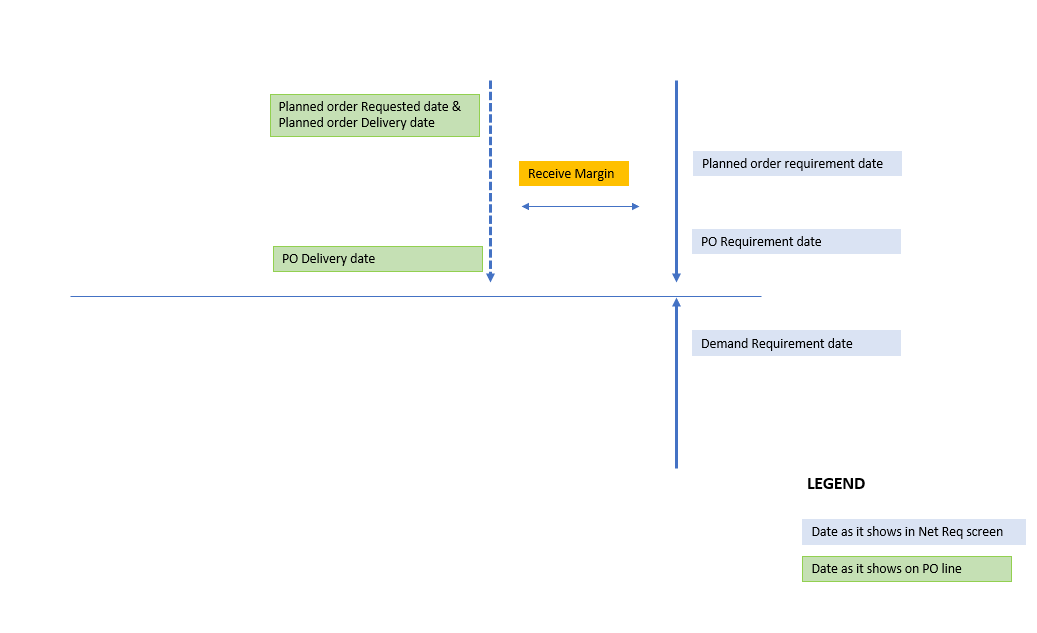

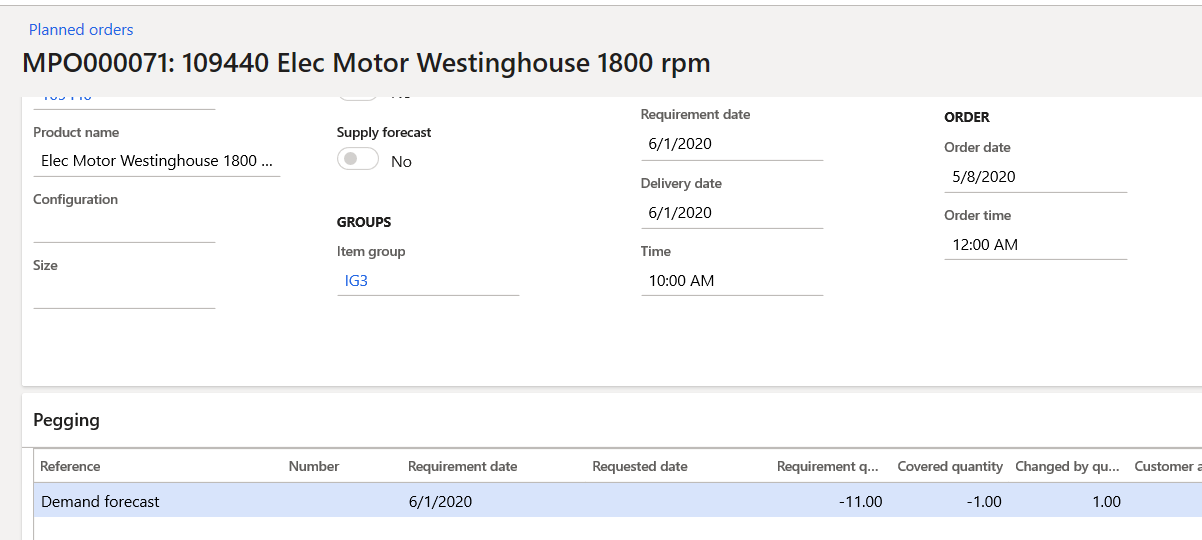

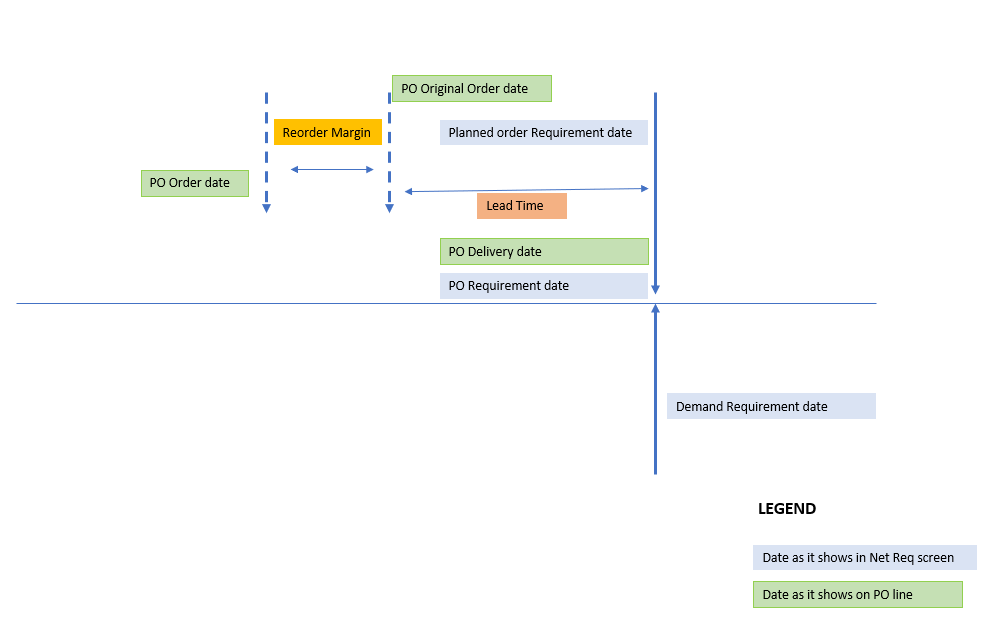

As a result, we see the three calendar days between the Requirement date and the Planned Purchase order Delivery date. But the Requirement date of the planned PO did not change. The official due date remains 6/1/2020. The Requested date is blank.

When I firm this planned order, my Purchase order Delivery date will be 05/29/2020.

MRP subtracts the receipt margin from the actual demand date.

Then why does the help text of the field talk about “Adding” to the requirement date? We will find out when looking at the Net requirement screen.

In the Net requirement screen, the Purchase order that has a delivery date of 5/29/2020 but it shows with a requirement date of 6/1/2020. This is the “adding!” The help text is written incorrectly. It should say “Receipt margin added to delivery date.”

What about “Requested date” in the Planned order grid? It shows as 5/29/2020. In this case, the Requested date is the corrected Requirement date using the Receipt margin.

CONCLUSION OF TEST 1: The receive margin safety time does not change the official planning dates, expressed in the “requirement date.” It is useful to “buy some time” for internal action after the PO has been received. This can also be true for Production orders when we require inspection after the Report as Finished transaction.

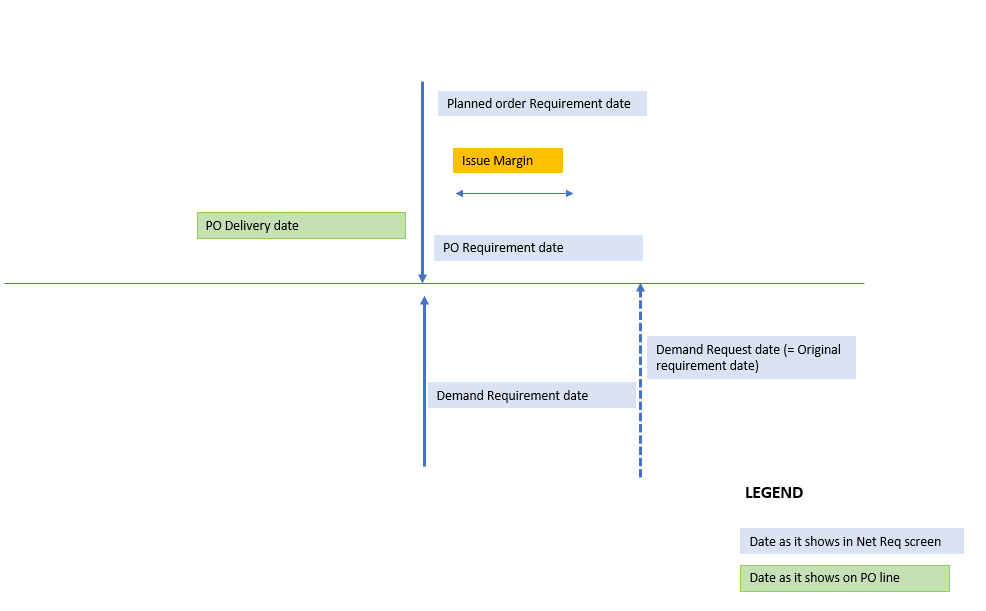

Master Planning Safety Margins TEST 2: Issue margin of 3 calendar days

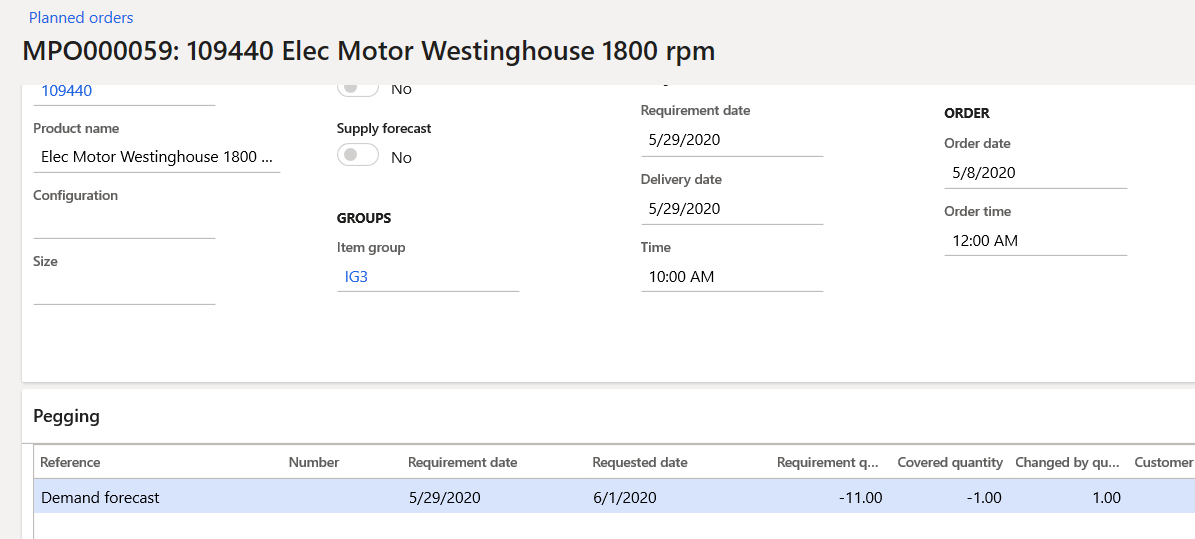

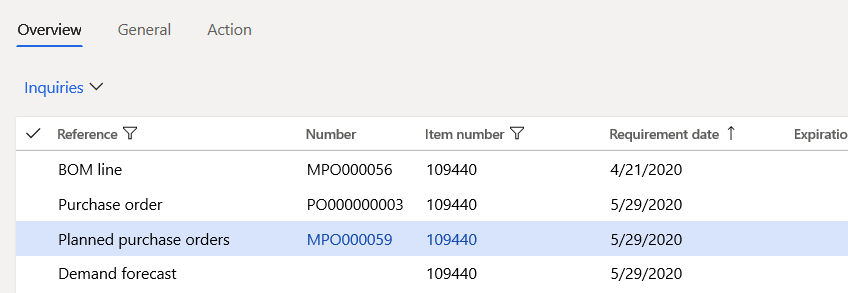

In this scenario, MRP changes the Requirements date of the demand. The official due date of the demand is now 5/29/2020. The Planned order Requirement date lines up with this new Requirement date. NOTE: The vendor won’t know the difference whether we use receipt margin or issue margin.

Note that the original demand date has been set back 3 days also.

There is a blank Requested date in the Planned orders grid.

In the Pegging section, the Requested date is 6/1/2020. This is the original demand date.

CONCLUSION OF TEST 2: The Issue margin creates an internal buffer by pretending that our demand (forecast, sales order, Production, or BOM line exploded demand) is earlier than it really is.

MRP really changes the requirement date of the demand. This scenario can be practical when we need some extra internal time in shipping, for example, for packaging and crating. We now have time for this. The alternative idea is to add an extra routing step so the production order can create this buffer, but this is not intuitive as packing and crating are warehouse activities that have nothing to do with manufacturing/production.

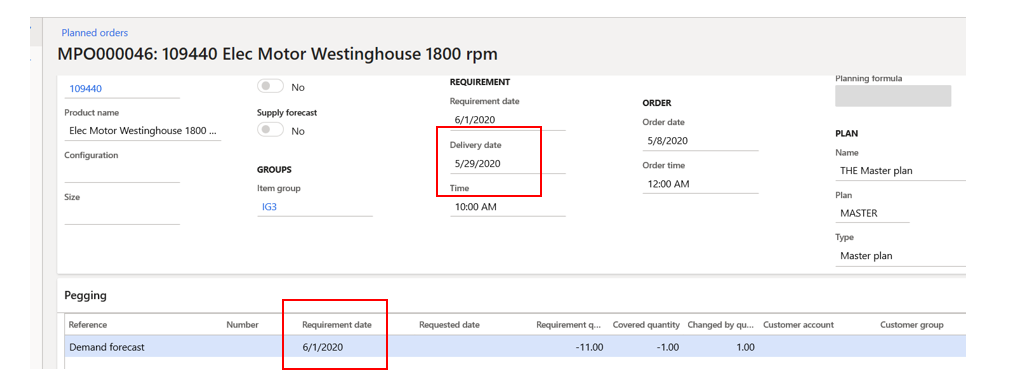

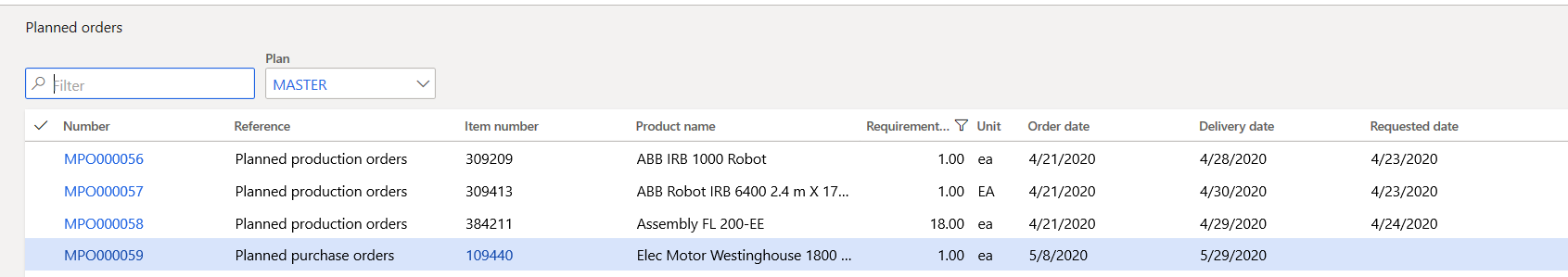

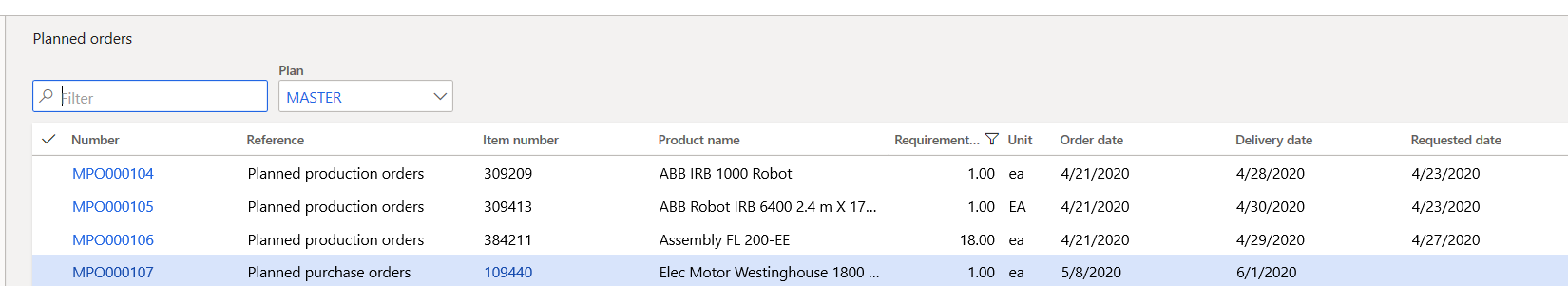

Master Planning Safety Margins TEST 3: Reorder margin of 3 days

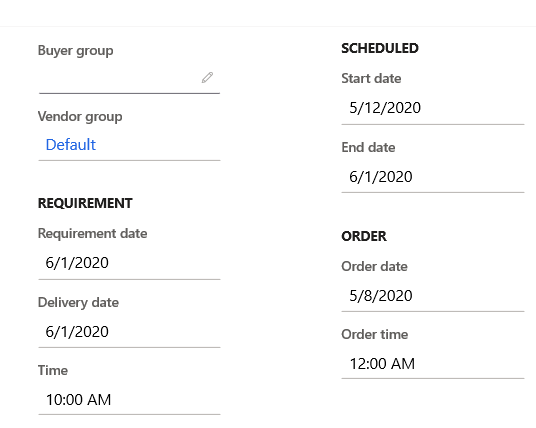

Testing the third margin parameter, we see that nothing is done with the Requirement date or Requested date. They stay exactly as they are. What is changing is one Order date.

A scheduled start date of 5/12/2020 is good enough to make my 6/1/2020 date (my lead time is 20 calendar days). But now, a reorder margin is “added to the item lead time.”

5/8/2020 to 5/12/2020, which is a generous three days! The point is that we have indeed extended the lead time. The supplier knows nothing different, and he will still aim for 6/1/2020.

The Requested date remains blank in the Planned orders grid.

CONCLUSION OF TEST 3: This scenario is suitable to buy us some time in the process of placing a new Purchase order. Maybe we have a very bureaucratic purchasing department where each PO has to be scrutinized. That could be a reason to define some reordering buffer time in planning. Or our production office needs extra time to get the shop package created and printed, find the drawings.

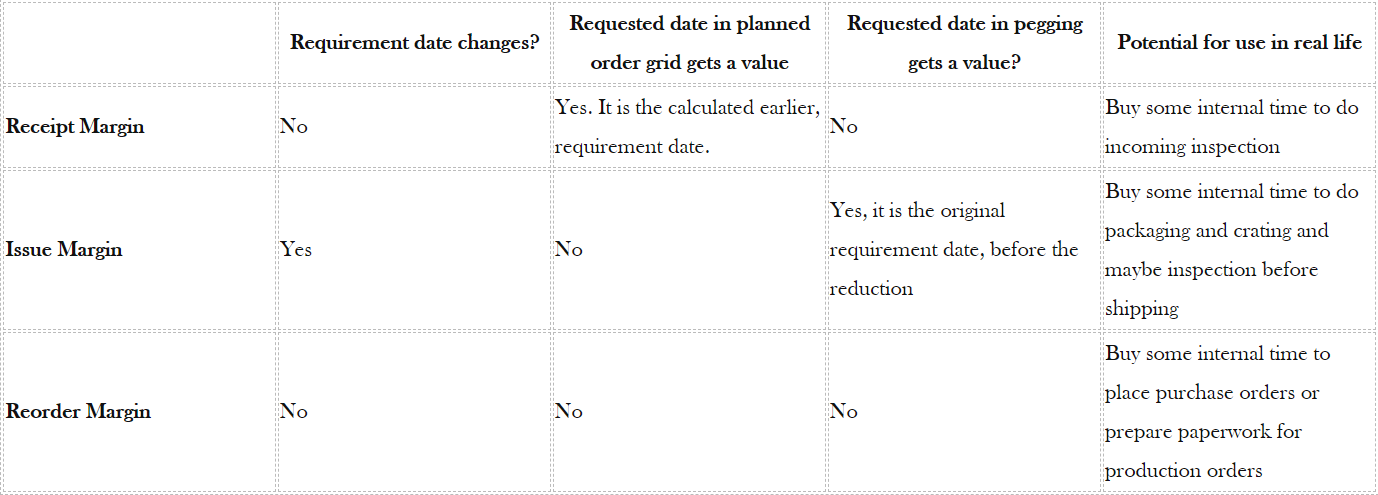

SUMMARY

Have any questions about using master planning safety margins? Our experts are ready to help!

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.