This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

D365 New Integrated Maintenance Functionality

An ERP system for manufacturing companies is not complete without functionality for maintenance.

However, it is not a forgone conclusion that maintenance should be part of the ERP system. Automation World recently examined the debate regarding whether it would fit better in an MES system than in an ERP system.

Microsoft has decided it fits in the ERP system. One can buy specialized third-party software dedicated to maintenance, but integration with the ERP system will be missing. Creating the integrations yourself is quite a task. Integration of maintenance with core ERP functionality has many advantages which we will discuss in this article.

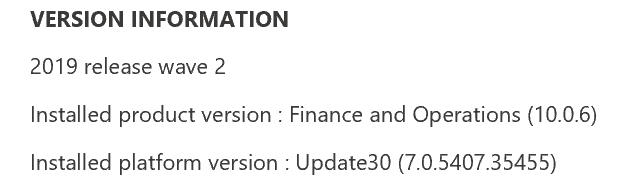

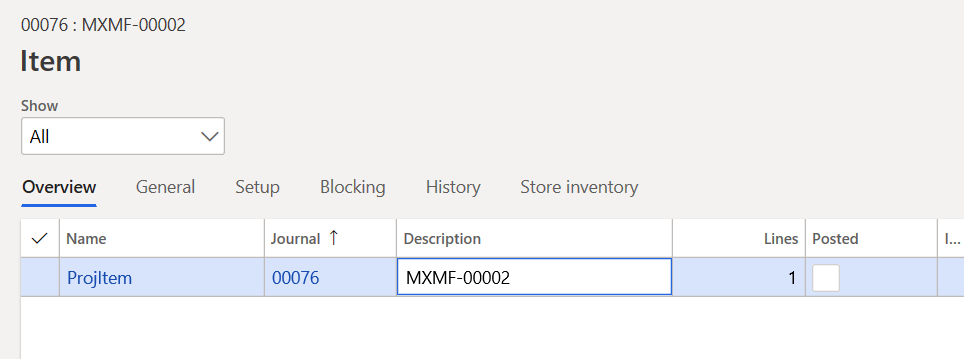

With update 30 of Microsoft Dynamics 365 for Finance and Operations (D365FO) we now have “Asset management” to work with. Let us review five important integration points.

Integrate with MRP and the production order scheduling system

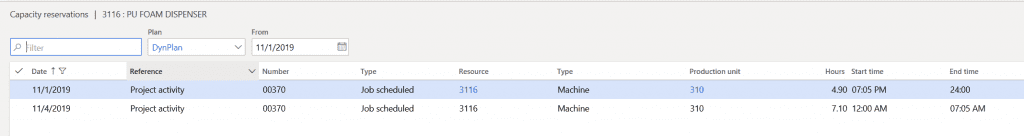

Machines under maintenance, scheduled maintenance or repair activities, should not be loaded with production order jobs. The production order jobs should be scheduled around maintenance. When the maintenance functionality for preventative maintenance is used, MRP will be asked politely to not schedule planned production orders on the dates that preventative maintenance is scheduled. Most maintenance operations may not take a full workday. In that case, MRP should reduce the day length of the working day to retain scheduling accuracy.

In D365, maintenance work would appear as a project activity in the scheduling system. The standard D365 system allows project activities to be scheduled just like production orders: operation or job scheduling. The nature of maintenance makes scheduling on the resource required, not on the group.

After a maintenance work order is scheduled, we see the maintenance work as a project job activity.

The hours of maintenance we see there are exactly what we see on the maintenance work order.

When we run Production order scheduling, we will see this maintenance workload. Only when using finite scheduling can we prevent the system from scheduling production orders on maintenance days.

Integrate with inventory management

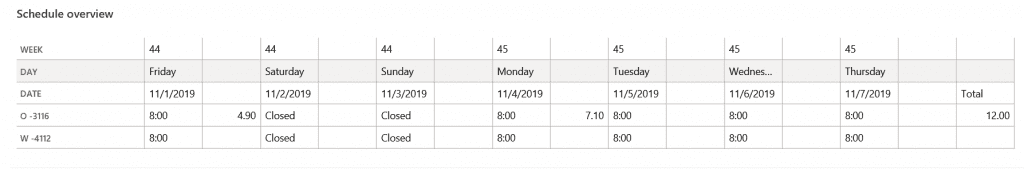

This is an obvious integration requirement. A maintenance department typically has their own warehouse with specific parts used in maintenance. The maintenance jobs should reserve and consume these parts just like a Field service work order would. As the maintenance work order is a project, a project item journal would be used to reserve and consume materials for maintenance. MRP can be used to reorder the materials and that way purchasing can take care of the Maintenance department easily.

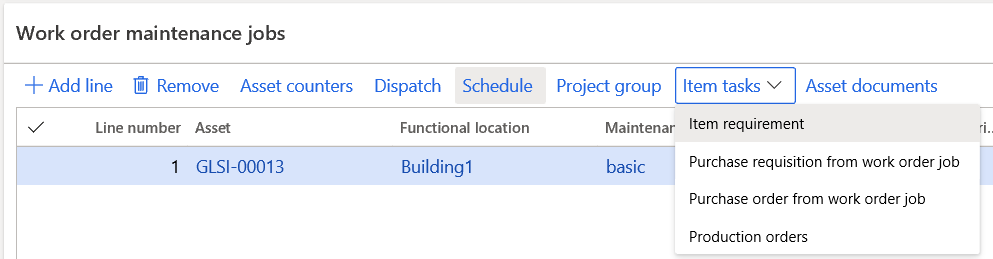

Above you see a project item journal with the maintenance work order in the description. Any materials needed for maintenance can be consumed this way. To request materials not in stock, the maintenance work order offers direct access to create a demand (Item requirement) or directly create purchase requisitions, purchase orders or even production orders.

NOTE: these are project purchase orders and production orders that will be directly issued to the project upon receipt. For production orders the project number does not automatically populate like it does for purchase orders.

Integrate with asset management

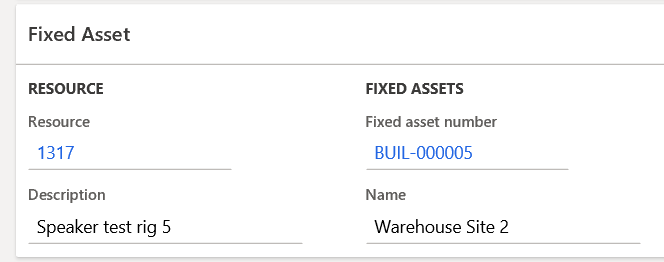

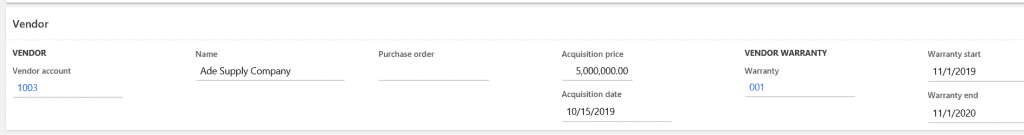

Machines are fixed assets with depreciation rules that should be listed in the Fixed assets module.

In the asset definition we see that we have a link to the fixed asset. The link must be created manually. But when we buy a new machine, we can have the PO receiving process create the fixed asset automatically. But the link with our resource in the production module must be created manually.

If the asset was purchased while D365 was live, there is possibility for additional information in the screen above.

Integrate with time and attendance

This is a very interesting integration and a very practical one. Because maintenance is often done by the same personnel that is working the machines in operational mode, the time and attendance reporting should allow the registration of time against maintenance jobs. The time reporting of maintenance will be against project activities. After approval they will translate into posted project hour journals. The system should allow to easily switch to time reporting on project activities from the regular time reporting on production orders.

This is indeed possible with the Job card terminal (not with the Job card device).

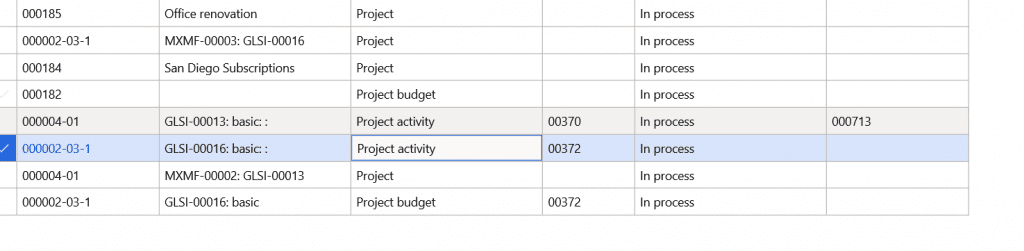

Above is the Job card terminal screen for project activities. The bottom rows are our maintenance work. GLSI numbers are our Asset numbers.

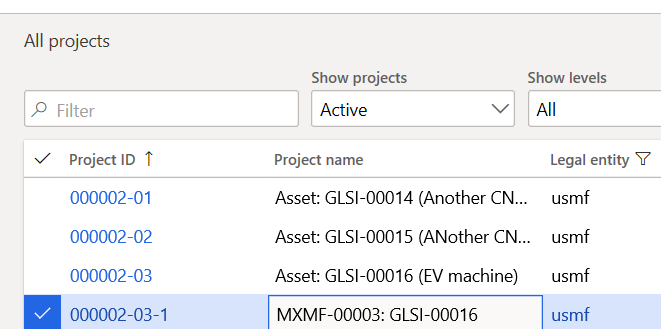

MXMF-00002 is a maintenance work order. It requires a little study on how the project numbers are working in Asset management.

Integration with Projects

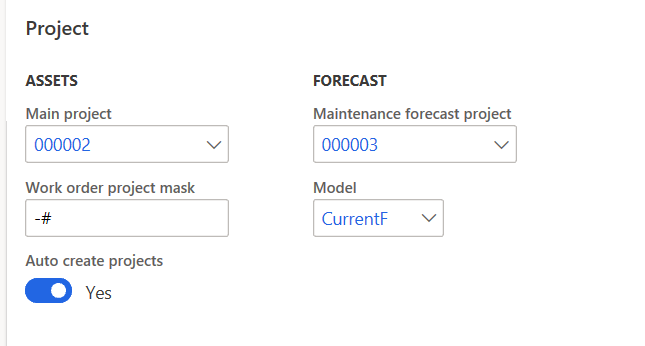

This is the fundamental integration. In the parameters the user defines a “mother project” for all assets. This is done in the Asset parameters and it is one of the most fundamental setups.

See below for different assets under the mother project 000002.

The maintenance work orders will become a sub-project of the asset-project, using the “mask” in the parameters to assign their number.

Integrate for Seamless Solutions

The new Asset Management module adds significant new functionality to the system. It is a pity that the navigation and setup is very different then the D365 user is accustomed too. This is unavoidable with the merging of 3d party software. It takes a while to learn to work with the system. This article only focused on integration, and there is overall good news for the integration points. We are getting the solid integration we expect, mostly thanks to the project module.

Have any questions about D365FO manufacturing maintenance? Contact us at any time!

This publication contains general information only and Sikich is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or any other professional advice or services. This publication is not a substitute for such professional advice or services, nor should you use it as a basis for any decision, action or omission that may affect you or your business. Before making any decision, taking any action or omitting an action that may affect you or your business, you should consult a qualified professional advisor. In addition, this publication may contain certain content generated by an artificial intelligence (AI) language model. You acknowledge that Sikich shall not be responsible for any loss sustained by you or any person who relies on this publication.